SikaWall®-85 Flash Seal NP

A composite, self-adhering flashing membrane.

SikaWall®-85 Flash Seal NP is a 32-mil thick, self adhering, self sealing, composite membrane of polyester fabric and butyl adhesive. SikaWall®-85 Flash Seal NP is supplied in rolls, on release paper, for easy application.

- Primerless application

- 180-day UV exposure when coated with Sika Facades barrier

- Remains flexible over time

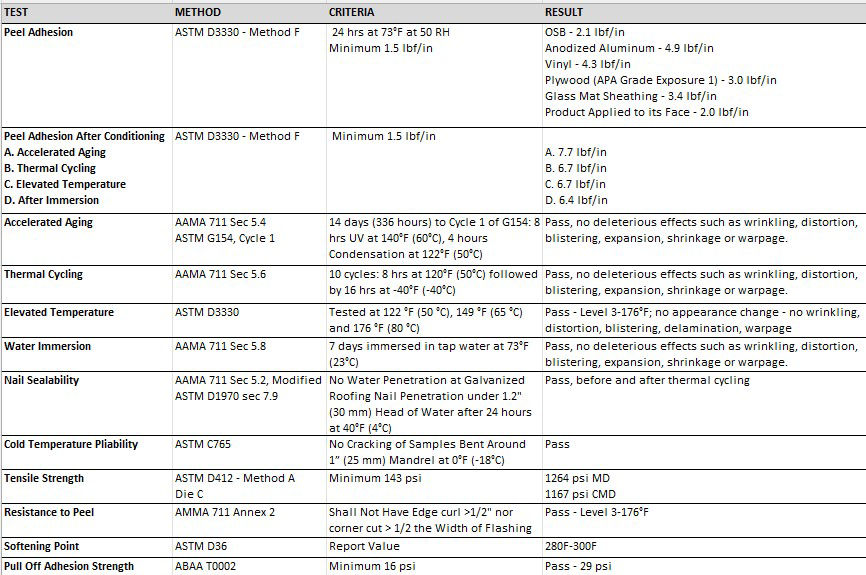

- Meets AAMA 711-13