PAREX® DPR Acrylic Finish

100% acrylic polymer finishes with advanced technology to improve long-term performance and dirt pick-up resistance. Integrally colored with high quality pigments.

- 100% Acrylic polymer chemistry creating long-term durability and weather resistance.

- Integral color reducing maintenance and the need for recoating.

- Repels water and resists wind-driven rain.

- Seals existing, non-moving hairline cracks. Doesn’t blister, peel or flake

Usage

PAREX® DPR Acrylic Finish provides enhanced protection for an aesthetically pleasing surface color and texture for Parex systems, poured concrete or unit masonry, conventional stucco, properly prepared insulating concrete forms and interior veneer plaster or gypsum wallboard (primer required over interior surfaces).Advantages

- 100% Acrylic polymer chemistry creating long-term durability and weather resistance.

- Integral color reducing maintenance and the need for recoating.

- Repels water and resists wind-driven rain.

- Seals existing, non-moving hairline cracks. Doesn’t blister, peel or flake

Packaging

5 gallon pail (19 liter pail)

Color

Available in a wide variety of standard and custom colors.

Product Details

Shelf Life

Two (2) years when properly stored in original container.

Storage Conditions

- Protect materials during transportation to avoid physical damage. Store in a cool, dry place protected from freezing, extreme heat and direct sun. Store at no less than 40°F (4°C)

- Do not stack pallets.

Grain size distribution

- DPR 530 Swirl Fine

- DPR 533 Sand Smooth

- DPR 534 Sand Fine

- DPR 535 Sand Coarse

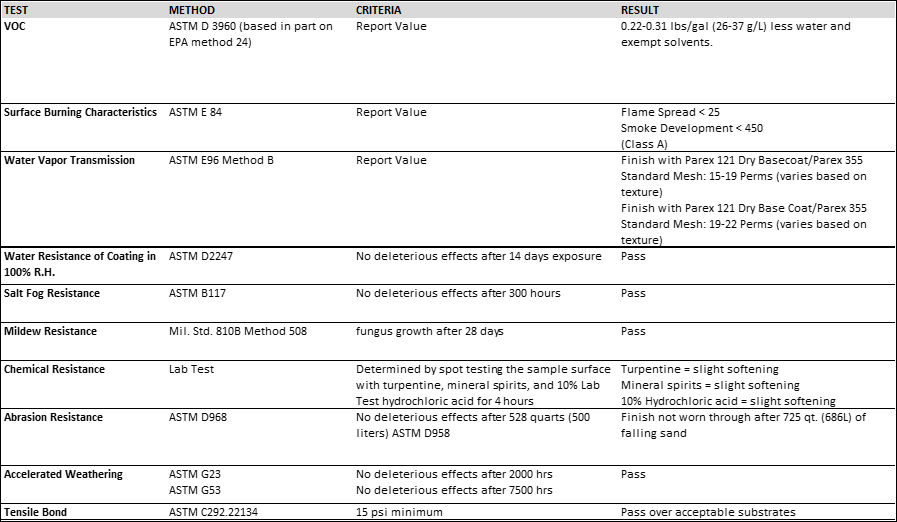

Test Results

Application

Ambient Air Temperature

- Protect from temperatures less than 40°F (4.5°C) for a minimum of 24 hours and until dry.

- When temperatures less than 40°F (4.5°C) prevail, provide supplementary heat during installation and drying period for at least 24 hours after installation and until dry.

- Do not apply in ambient temperature above 100°F (38°C) or surface temperature above 120°F (49°C).

Cure Time

- Finish will be dry within 24 hours. Drying time is dependent on humidity, air temperature, sun exposure, surface conditions and finish thickness. Lower temperature, higher humidity and application in shaded areas will extend drying time.

- Protect finish from rain or other precipitation and temperatures less than 40°F (4.5°C) for a minimum of 24 hours and until dry.

Coverage

DPR 530 Swirl Fine: 130 to 140 ft2 (12 to 13 m2)

DPR 533 Sand Smooth: Smooth 182-187 ft2 (17 m2) at two (2) coats.

DPR 533 Sand Smooth: Skip Trowel 150-160 ft2 (17 m2)

DPR 534 Sand Fine: 145 to 155 ft2 (13.5 - 14.4 m2).

DPR 535 Sand Coarse: 105 to 115 ft2 (9.8 - 10.7 m2).

* Coverage rates vary depending on porosity of substrates and application techniques.

SUBSTRATE PREPARATION

Substrates must be clean, dry, sound and free of loose material, releasing agents, paint, efflorescence, contaminants and other coatings. Use of SikaWall-15 Tinted Primer can improve color uniformity by minimizing substrate read-through in light colors.

- Concrete: allow to cure a minimum of 28 days prior to application of primer or finish.

- Unit Masonry: allow to cure prior to application of primer or finish. When needed, apply a leveling coat of Parex 121 Dry Basecoat to provide a smooth surface and minimizethe likelihood of mortar joint read through prior to application of finish.

- Stucco: allow to cure a minimum of 6 days prior to application of primer or finish.

Note: Primer is for color uniformity, not for adhesion assistance.

MIXING

Thoroughly mix the factory prepared finish with a paddle and low speed drill to a uniform workable consistency. A small amount of clean potable water may be added to adjust workability. Do not exceed 10 oz. of water per 5-gallon pail.

- Additives are not permitted.

- Close container when not in use.

- Clean tools with soap and water immediately after use. Dried material can only be removed mechanically.

APPLICATION

- Apply finish directly to the substrate (or primed substrate) with a clean, stainless steel trowel. Apply and level finish during the same operation to minimum obtainable thickness consistent with uniform coverage.

- Maintain a wet edge on finish by applying and texturing continually over the wall surface. Work finish to corners, joints or other natural breaks and do not allow material to set up within an uninterrupted wall area.

- Float finish to achieve final texture.

Note: DPR Sand Smooth Finish

For smooth application, allow the first coat of Sand Smooth finish to dry prior to applying a second coat. 2 coats are required for a smooth texture.

For free-formed application including stipple and skiptrowel, maximum thickness not to exceed 1/8” (3.2mm).