PROTOTYPING SYSTEMS | POLYURETHANES & MOLD MAKING SILICONES

Easy Processing | Durable | Exceptional Properties

| Product PDS | Resin SDS | Hardener SDS | Flexural Modulus (psi) | Pot Life (min/g) | Tg (°F) | Shore Hardness | Cured Color | Description |

|---|---|---|---|---|---|---|---|---|

| PX 1000 NA | PX 1000 NA | PX 1000 NA | 200,000 | 17/200 | 167 | 78 D | Off-white | Casting system for simulating thermoplastic-like parts, mock ups, and prototypes |

| TCC-8020 | TCC-8020 | TCC-8021 | 237,500 | 17/150 | 140 | 75 D | White | System for simulating RIM parts, polypropylene parts with thermoplastic characteristics, fastcast, and rapid prototyping |

| PX 523 | PX 523 | PX 5210 | 321,000 | 17/156 | 237 | 85 D | Clear | UV-resistant system for crystal clear, glass/ polycarbonate-like, mock up, and prototype parts for high temperature applications |

| SikaBiresin® PX224 | PX224 | 224UF | 330,300 | 1 - 2/150 | 208 | 83 D | Lt. Amber | Casting system for vacuum or hand casting used to make high impact strength prototype parts. Extremely tough and impact resistant with exceptional hardness and a base that readily accepts color for a range of pigments and thus cured colors |

| 224F | 3 - 4/150 | 216 | ||||||

| 224 | 6 - 9/150 | 201 | ||||||

| 224L | 386,000 | 12 - 16/150 | 213 | 85 D | ||||

| PX 223 HT | PX 223 HT | PX 223 HT | 334,000 | 6/90 | 248 | 80 D | Black | System for parts out of HIPS (High Impact Polystyrene) with superior heat and impact resistance |

| Product PDS | Resin SDS | Hardener SDS | Shore Hardness | Tear Resistance (ppi) | Cured Color | Mixed Viscosity (cps) | Description |

|---|---|---|---|---|---|---|---|

| ESSIL 125 NA | ESSIL 125 NA | ESSIL 125 NA B | 30 A | 100 | White | 20,000 | Condensation (tin) cure silicone for resin casting, fastcast urethanes, and epoxies |

| ESSIL 125 NA Fast Blue | Blue | ||||||

| AX-SIL 4240 | AX-SIL 4240 A | AX-SIL 4240 B | 38 A | 120 | Translucent | 40,000 | Addition (platinum) cure silicone ideal for reproducing intricate details. Maintains close tolerances for mold-making from 3D printers |

| ESSIL 245-255 | ESSIL 245 | ESSIL 255 | 53 A | 75 | Gray | 25,000 | Addition (platinum) cure silicone with high strength and excellent release for pattern/model shop mold making and tooling applications |

| Product PDS | Resin SDS | Hardener SDS | Pot Life (min/g) | Shore Hardness | Mixed Color | Mixed Viscosity (cps) | Elongation (%) | Description |

|---|---|---|---|---|---|---|---|---|

| TCC-5000A/5050B | TCC-5000A | TCC-5050B | 15 - 20/150 | 50 A | Amber | 1,000 | 500 | Exceptionally tough system for flexible molds, nesting fixtures, metal forming pads, belts, and sound damping pads |

| TCC-5000A/5060B | TCC-5060B | 60 A | Amber | 1,000 | 600 | |||

| TCC-5000A/5070B | TCC-5070B | 70 A | Amber | 1,000 | 500 | |||

| TCC-5000A/5080B | TCC-5080B | 12 - 14/150 | 80 A | Amber | 1,500 | 400 | ||

| TCC-5000A/5090B | TCC-5090B | 15 - 20/150 | 90 A | Opaque Cream | 2,500 | 300 | Exceptionally tough system for flexible molds, nesting fixtures, metal forming pads, and industrial rollers | |

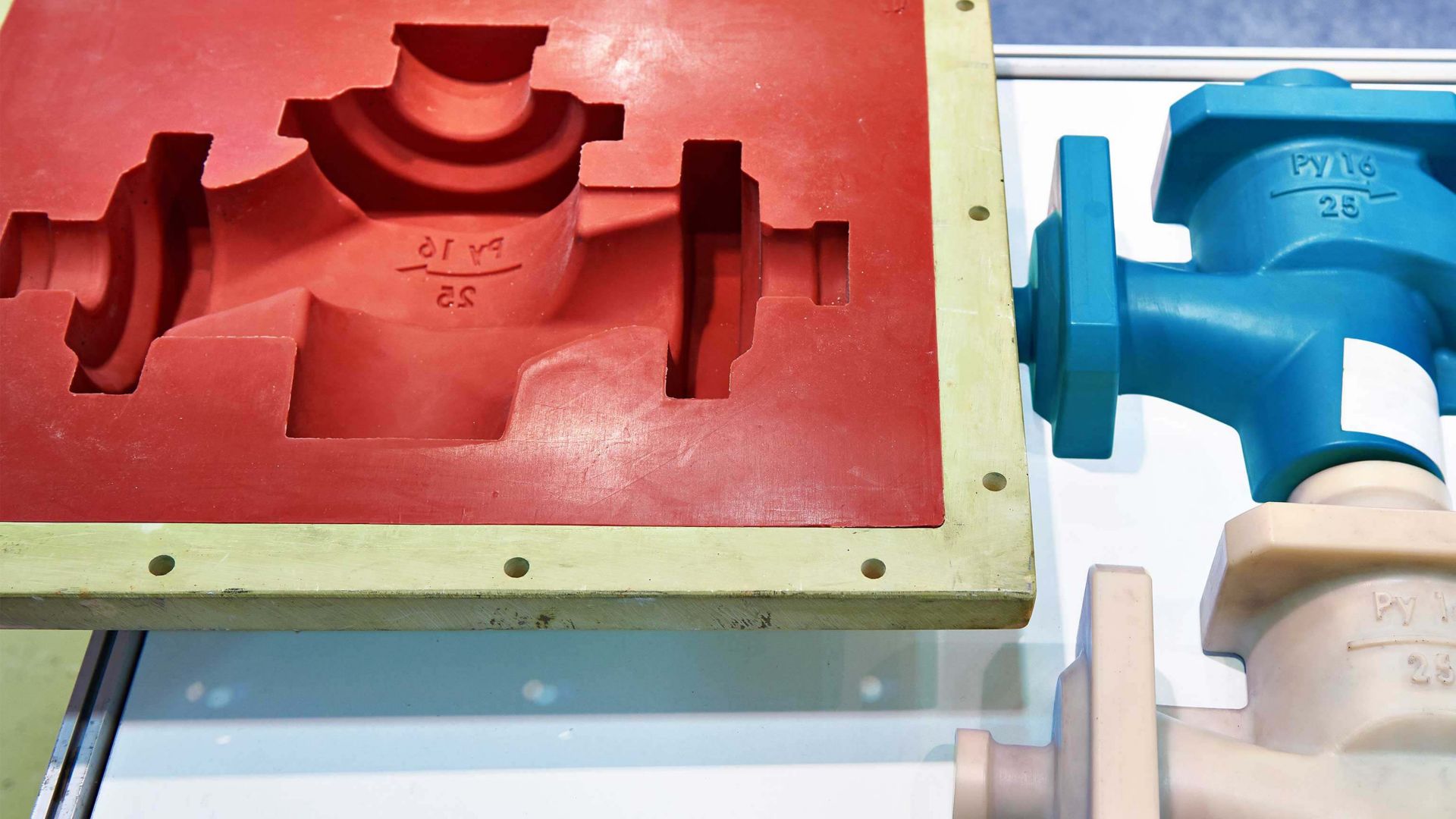

| UR 3558 A/B | UR 3558A | UR 3558B | 25/142 | 95 A | Amber | 3,000 | 460 | High abrasion and impact-resistant urethane for foundry tooling |

| TCC-6060 A/B | TCC-6000A | TCC-6060B | 12 - 15/453 | 60 D | Amber | 2,500 | 200 | Impact-resistant; low shrinkage system for molds, foundry patterns, core box liners, industrial rollers, and shims |

| UR 3490 A/B | UR 3490A | UR 3490B | 14/150 | 67 D | Beige | 1,500 | 120 | Impact-resistant surface casting urethane for foundry tooling, patterns, and core boxes |

| Product PDS | Resin SDS | Hardener SDS | Pot Life (min/g) | Shore Hardness | Cured Color | Mixed Viscosity (cps) | Tg (°F) | Description |

|---|---|---|---|---|---|---|---|---|

| HH Extreme A/B | HH Extreme A | HH Extreme B | 2/94 | 72 D | Off-White Translucent | 350 | 120 | Versatile, tough, durable, easily tintable. Impact, wear, and moisture-resistant system for handholds in the climbing industry |

| F100A/B | F100A | F100B | 5/300 | 82 D | Gray | 2,500 | 225 | Filled, dimensionally stable, heat-resistant. Easily re-mixed system for checking/nesting fixtures, core boxes, thermoforming tools, and prototyping parts |

| F100A (Medium)/B | F100A (Medium) | 9/200 | 80 D | Blue | 2,500 | 158 | ||

| F100 A (LPL)/B | F100 A (LPL) | 14/200 | 79 D | Gray | 2,500 | 128 | ||

| TCC-8020A/8021B | TCC-8020A | TCC-8021B | 17/150 | 75 D | White | 150 | 140 | System for simulating RIM parts, polypropylene parts with thermoplastic characteristics, fastcast, and rapid prototyping |