Epoxy Casting Systems | Surface & Mass Casting

FOR FILLED TOOLING SYSTEMS • VARIABLE CASTING THICKNESS AVAILABLE

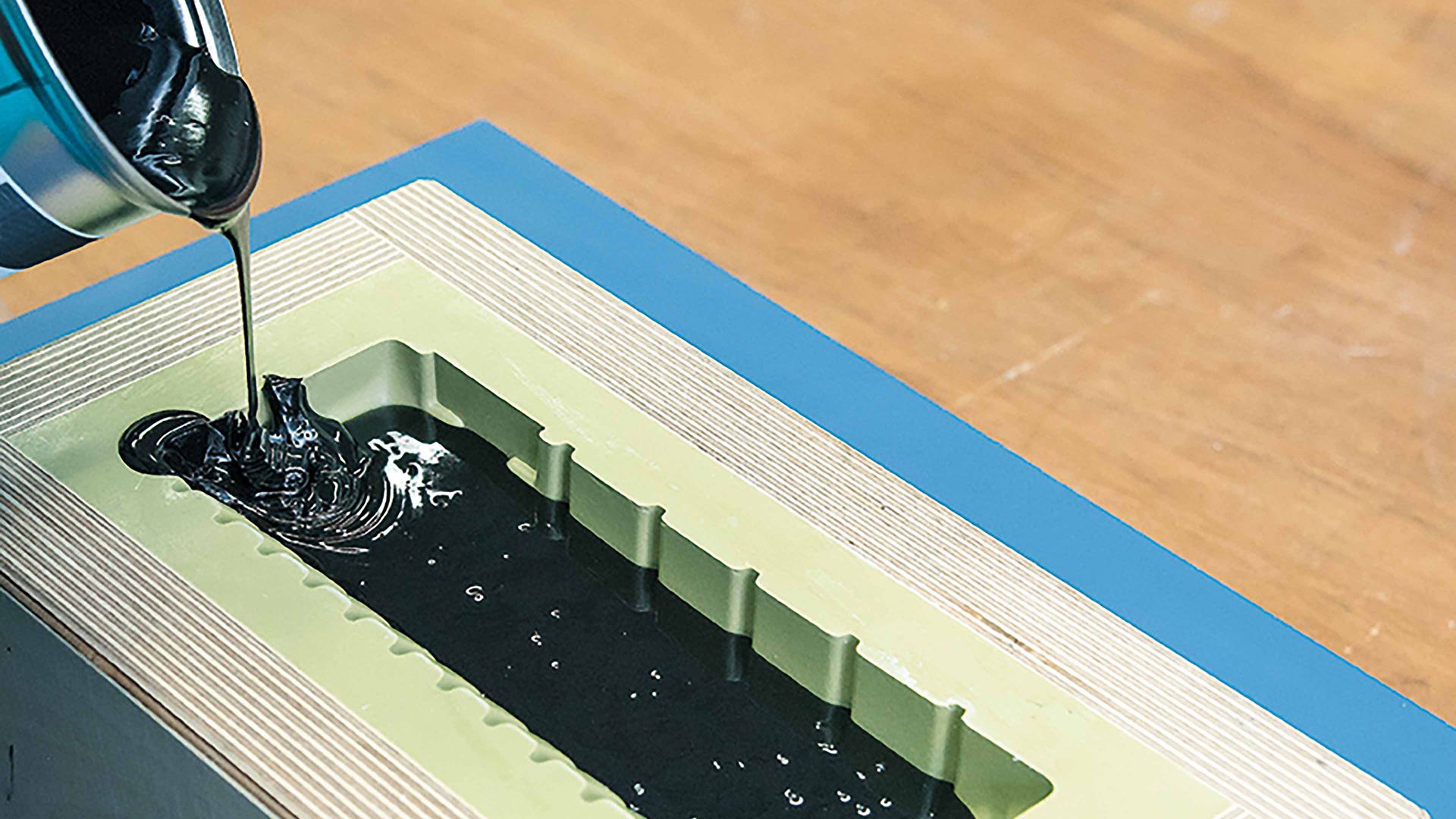

Epoxy resins used in surface and mass casting, specifically for filled tooling systems.

Room temperature and high temperature options are available. (See below)

| Product [PDS] | Resin [SDS] | Hardener [SDS] | Tg (°F) | Shore Hardness | Max Casting Thickness | Cured Color | Pot Life (min/g) | Description & Applications |

|---|---|---|---|---|---|---|---|---|

| AC 2310 | AC 2310 | AC 2310 (Slow) AC 2310 (Fast) | 160 | 93 D | 2" | Gray | 240/440 | Abrasion-resistant system for stretch forms, hydroform, and drop hammer dies |

| TCC-401 | TCC-401 | TCC-104 | 180* | 80 D | < 1” | Black | 30/500 | Abrasion-resistant, iron-filled system for cast hydroform tools, stretch form blocks, and metal forming dies |

| TCC-104-5 | 180* | 80 D | < 4” | Black | 50/500 | |||

| TCC-105 | 180* | 80 D | > 4” with bulk fill | Black | 90/500 | |||

| TCC-410 | TCC-410 | TCC-104 | 180* | 84 D | < 1” | Gray | 60/500 | Aluminum-filled, impact-resistant system for surface casting on prototype stamping dies |

| TCC-104-5 | 210* | 84 D | < 4” | Gray | 100/500 | |||

| TCC-105 | 240* | 84 D | > 4” with bulk fill | Gray | 150/500 | |||

| EC-440 | EC-440 | EC-440 | 208 | 95 D | 6” | Lt. Amber | 70/260 | Binder resin for ceramic-filled casts and backfilling of nickel shell mold surfaces. Requires use of N5/N51 fillers |

| TCC-626 | TCC-626 | TCC-116 A | 217 | 85 D | 1” | Black | 120/500 | Impact-resistant system with excellent thermal shock for surface casting applications |

| *Peak Operating Temperature | ||||||||

| Product [PDS] | Resin [SDS] | Hardener [SDS] | Tg (°F) | Shore Hardness | Max Casting Thickness | Cured Color | Pot Life (min/g) | Description & Applications |

|---|---|---|---|---|---|---|---|---|

| EC-439 | EC-439 | EC-439 | 270 | 89 D | 6” | Lt. Amber | 180/260 | Binder resin for ceramic-filled cast tooling for low volume production of RIM, RTM, and cold comperssion molds. Requires use of N5/N50 fillers |

| EC-433 | EC-433 | EC-433-4 (Slow) | 285 | 91 D | < 3” | Gray | 270/1,356 | Aluminum-filled system for production of vacuum form molds, prototype plastic injection molding, RIM, and back filling of laminated or spray metal mold surfaces |

| EC-344-2 (Fast) | 288 | 90 D | < 1” | Gray | 120/336 | |||

| EC-433-3 (Medium) | 305 | 90 D | 1” | Gray | 200/1,356 | |||

| EC-415 | EC-415 | EC-415 | 428 | 89 D | 3” | Gray | 150/200 | Aluminum-filled system with excellent thermal conductivity for cast autoclave molds, plastic injection molds, and compression molding applications |