Sika Advanced Resins Epoxy Lamination Systems l Pro’s Choice Goalie Masks

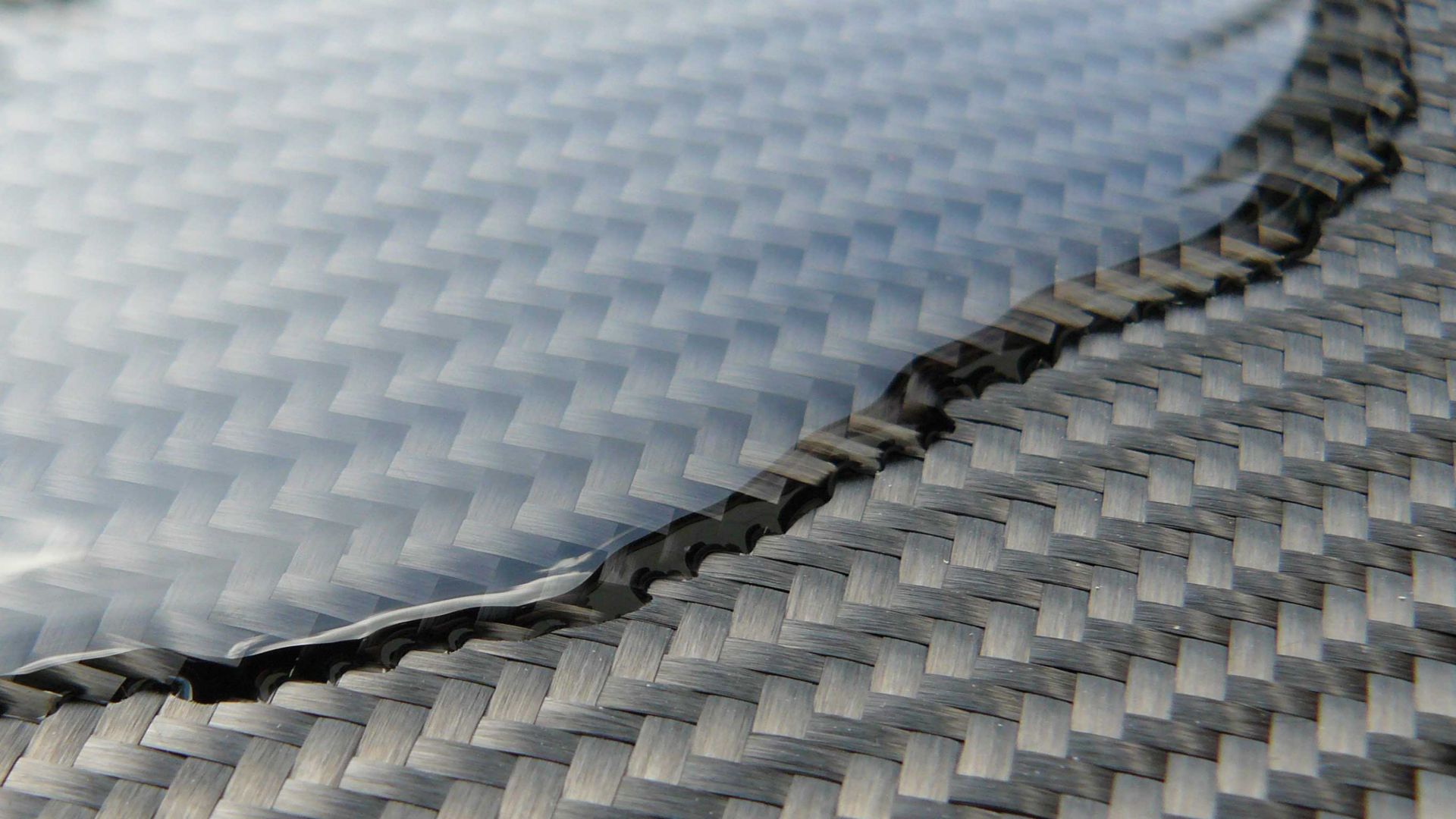

Shown at right: Pro’s Choice is a leading manufacturer of composite-based, custom-fit, hockey goalie masks.

Hear from owner, Dom Malerba, as to why he trusts Sika’s epoxy lamination systems to help ensure his masks perform to the highest safety and quality standards.

Epoxy Lamination Systems | Room & High Temperature

HIGH PERFORMANCE • BROAD RANGE OF APPLICATIONS

| Product PDS [Formerly] | Resin SDS [Formerly] | Hardener SDS [Formerly] | Tg (°F) | Mix Ratio | Cured Color | Mixed Viscosity (cps) | Pot Life (min/g) | Description & Applications |

|---|---|---|---|---|---|---|---|---|

| SikaBiresin® CR77 FR [EL-319] | SikaBiresin® CR77 FR (A) [EL-319 (A)] | SikaBiresin® CH77-2 (B) Fast [EL-319 (B) Fast] | 120 | 100/12 | Lt. Amber | 1,780 | 36/200 | Flame-retardant (FAR 25.853), UV-resistant. halogen-free system for composite parts |

| SikaBiresin® CH77-4 (B) Slow [EL-319-1 (B) Slow] | 100/19 | 900 | 108/200 | |||||

| SikaBiresin® CR62 FR [EL-320] | SikaBiresin® CR62 FR (A) [EL-320 (A)] | SikaBiresin® CH62 (B) [EL-320 (B)] | 140 | 100/10 | Lt. Amber | 2,650 | 45/200 | Flame-retardant (FAR 25.853) system for composite parts |

| SikaBiresin® CH62-1 (B) Fast [EL-320-1 (B)] | 100/17 | 1,700 | 16/200 | |||||

SikaBiresin® CR96 FR [EL-322] | SikaBiresin® CR96 FR (A) [EL-322 (A)] | SikaBiresin® CH96-2 (B) [EL-322 (B)] | 100/16 | Lt. Amber | 550 | 49/100 | Halogen-free, flame retardant, epoxy laminating and infusion system developed for use in fabricating parts or repairs on structures that require flame retardant, self-extinguishing properties with room-temperature curing capabilities. | |

| AL 2020 | AL 2020 | AL 2021 H | 154 | 100/22 | Clear | 1,000 | 65/100 | Flame-retardant (FAR 25.853), unfilled system used with glass, carbon, aramid or hybrid fabrics. Ideal for high performance parts meeting NASCAR fire retardant requirements. Suitable for vacuum bagging and RTM. Can be heated immediately for faster process times |

| AL 2022 H | 100/24 | 1,300 | 210/100 | |||||

| AL 2023 H | 100/30 | 1,300 | 570/100 | |||||

| SikaBiresin® L323 [EL-323TC] | SikaBiresin® L323 (A) [EL-323TC A] | SikaBiresin® L323 (B) [EL-323TC B] | 160* | 100/93 | Green | Dough | 120/400 | Moldable epoxy dough-like compound for composite duplicating aids, jigs & fixtures |

| EL-302PC | EL-302PC | EL-302PC H | 170* | 100/16 | White | 3,000 | 31/232 | General purpose epoxy tooling resin with good fabric wet-out properties. Used for duplicating aids, jigs, and fixtures |

| EL-302PC-2 H | 100/19 | 3,000 | 60/200 | |||||

| SikaBiresin® CR72 (Marine 820) | SikaBiresin® CR72 (Marine 820) | CH72-1 (Marine 822) | 180 | 100/18 | Lt. Amber | 650 | 30/200 | UV-resistant, general purpose, low viscosity system used for fabrication of laminated or infusion molded composite parts and structures |

| CH72-2 (Marine 823) | 350 | 45/200 | ||||||

| CH72-3 (Marine 824) | 425 | 60/200 | ||||||

| TCC-205 | TCC-205 | TCC-102 H | 180* | 100/25 | Amber | 700 | 17/100 | Unfilled, general purpose laminating and board adhesive |

| TCC-104 H | 800 | 32/100 | ||||||

| SikaBiresin® CR88 [Epolam 2015] | SikaBiresin® CR88 (A) [Epolam 2015 A] | SikaBiresin® CH88-6 (B) [Epolam 2015 B] | 190 | 100/32 | Clear | 550 | 140/500 | Marine system for production of composite structures and tooling by hand layup, RTM, and infusion methods |

| Product PDS [Formerly] | Resin SDS [Formerly] | Hardener SDS [Formerly | Tg (°F) | Mix Ratio | Cured Color | Mixed Viscosity (cps) | Pot Life (min/g) | Description & Applications |

|---|---|---|---|---|---|---|---|---|

| TCC-230 | TCC-230 | TCC-102 H | 200* | 100/17 | Amber | 4,000 | 5/100 | Unfilled, general purpose laminating and board adhesive |

| TCC-104 H | 200* | 20/100 | ||||||

| SikaBiresin® CR101 [EL-335] | SikaBiresin® CR101 (A) [EL-335] | SikaBiresin® CH101-2 (B) [EL-335 (B)] SikaBiresin® CH101-3 (B) [EL-335-2 (B)] | 212 | 100/20 | Lt. Amber | 1,500 | 50/228 | High performance, impact resistant, toughened system for composite parts |

| Epolam 2500 | Epolam 2500 | Epolam 2500 H | 212 | 100/22 | Beige | 1,800 | 90/500 | Flame retardant system (FAR 25.853 compliant) for composite parts |

| SikaBiresin® L337 [EL-337] | SikaBiresin® L337 (A) [EL-337 (A)] | SikaBiresin® L337 (B) [EL-337 (B)] | 238 | 100/16 | Gray | 4,000 | 50/232 | Good room temperature curing properties system for laminated vacuum form, RIM, and RTM molds |

| SikaBiresin® CR128 [EL-336] | SikaBiresin® CR128 (A) [EL-336 (A)] | SikaBiresin® CH128-2 (B) [EL-336 H (B)] SikaBiresin® CH128-4 (B) [EL-336 LPL (B)] | 262 | 100/22 | Amber | 2,500 | 40/228 | |

| SikaBiresin® CR163 [EL-315] | SikaBiresin® CR163 (A) [EL-315 (A)] | SikaBiresin® CH163-1 (B) [EL-315-1 (B)] | 305 | 100/19 | Black | 2,500 | 55/100 | Unfilled system for laminated carbon fiber or E-glass composite tools requiring heat resistance |

| SikaBiresin® CH163-2 (B) [EL-315-IHL (B)] | 331 | 100/25 | Amber | 3,250 | 63/100 | |||

| SikaBiresin® CH163-6 (B) [EL-315-2 (B)] | 450 | 100/24 | Amber | 4,500 | 200/100 | |||

| SikaBiresin® CR216 [Epolam 2090] | SikaBiresin® CR216 (A) [Epolam 2090 (A)] | SikaBiresin® CH216-50 (B) [Epolam 2026 (B)] | 401 | 100/53 | Amber | 650 | 1,500/150 | Ultra-high temperature system for production of composite tooling and structures by vacuum bagging and infusion processes |

| SikaBiresin® L325 HT [EL-325 HTTC] | SikaBiresin® L325 HT (A) [EL-325 HTTC (A)] | SikaBiresin® L325 HT (B) [EL-325 HTTC (B)] | 425 | 100/25 | Gray | Dough | 105/454 | Ultra-high temperature, moldable dough-like compound used for composite vacuum forms, RIM, and RTM molds |

| SikaBiresin® CR226 [Epolam 2092] | SikaBiresin® CR226 (A) [Epolam 2092 (A)] | SikaBiresin® CH226-20 (B) [Epolam 2092 (B)] | 437 | 100/50 | Amber | 550 | 400/500 | Ultra-high temperature, heat curing epoxy infusion system for composite molds and structures |