SikaBond®-150 Premium Floor

Universal Pressure Sensitive Acrylic Adhesive for all flexible coverings

0.0 (0)

SikaBond®-150 Premium Floor is a 1-component, solvent-free, universal pressure-sensitive dispersion adhesive.

- Up to 8 hours of working time

- Very easily spread

- Low consumption / high coverage

- High initial adhesion power

- Suitable for wet and semi-wet bonding

- Suitable for use with underfloor heating

- Suitable for use with castor-chairs

- Suitable for shampooing

- Suitable for difficult coverings

Usage

SikaBond®-150 Premium Floor is designed for full surface bonding of mentioned below floor coverings on absorbent and non-absorbent substrates in interior areas: Luxury vinyl tiles (LVT) Woven fabrics Linoloum coverings Single or multilayer needle felting Natural fibre coverings with backing Impact sound insulation underlays Carpets with PVC, PU or filler-free backing Corkment and cork linoleum PVC and cushioned vinyl (CV) floor coverings Rubber floor coverings in sheets Rubber floor coverings as tilesAdvantages

- Up to 8 hours of working time

- Very easily spread

- Low consumption / high coverage

- High initial adhesion power

- Suitable for wet and semi-wet bonding

- Suitable for use with underfloor heating

- Suitable for use with castor-chairs

- Suitable for shampooing

- Suitable for difficult coverings

Packaging

4 gallon (18 kg) pail

Color

Beige

Product Details

ENVIRONMENTAL INFORMATION

- EMICODE EC1PLUS

APPROVALS / STANDARDS

- Marine Equipment Directive (MED, "wheelmark")

Chemical Base

1-Component dispersion

Shelf Life

1 year in original unopened packaging.

Storage Conditions

+41°F (+5°C) to +77°F (+25°C) The product must be stored in original, unopened and undamaged sealed packaging in dry conditions.

Density

| 75 lbs/ft3 (1.20 kg/l) | (ISO 1183-1) |

Consistency

Middle viscous, spreads very easily

Service Temperature

+41°F (+5°C) to +95°F (+35°C)

Application

Ambient Air Temperature

Room temperature between +59°F (+15°C) and +95°F (+35°C). For ambient temperatures standard construction guidelines should be followed. Follow all wood floor manufacturers’ acclimation and room temperature requirements.

Relative Air Humidity

Between 40 % and 60 % during installation is best for adhesive. See wood floor manufacturer for wood requirements.

Substrate Temperature

During laying and until SikaBond®-150 Premium Floor has fully cured, substrate temperature should be greater than +60 °F (+15 °C) and in the case of radiant floor heating, less than +70 °F (+20 °C). For substrate temperatures, standard construction guidelines should be followed.

Substrate Moisture Content

Where moisture readings exceed 15 lbs / 1000 sq. ft / 24 hrs or 95% RH (or 9 lbs / 90% RH prior to install linoleum or rubber)

Cure Time

24 hrs (final strength after 72 hrs)

Flash-off Time

0–120 minutes (depending on laying method and porousity)

Application Time

20 minutes - up to 8 hours (depending on laying method and pourosity)

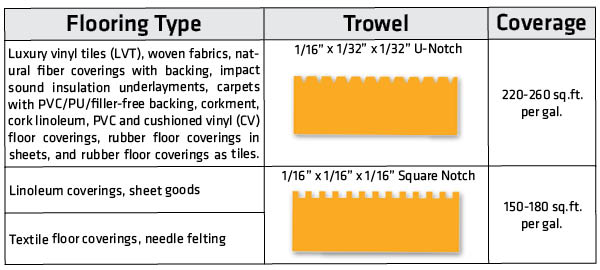

Coverage

-

Coverage must be monitored to ensure accuracy of application. Trowel angle may prevent proper coverage.

-

Applicator is responsible for periodic inspection of the trowel to check for excessive wear. Worn trowels must be replaced immediately.

-

In case of uneven substrates, it may be necessary to use a notched trowel with bigger notches (avert hollow sections).

-

Coverage must be monitored to ensure accuracy of application. Trowel angle may prevent proper coverage.

-

Trowel size is recommended to obtain proper coverage, larger sizes are acceptable. Excessive amounts of adhesive may cause flooring to slide while placing check coverage during installation.

-

Substrate Quality: Structurally sound, clean, dry, homogeneous, even, free from grease, dust and loose particles, paint, laitance, and other poorly adhering particles must be removed.

APPLICATION INSTRUCTIONS

For the application of SikaBond®-150 Premium Floor all standard construction guidelines and relevant valid data sheets apply.

SUBSTRATE PREPARATION

- The substrate must be clean, dry, sound and homogeneous, free from oils, grease, dust and loose or friable particles. Paint, cement laitance and other poorly adhering contaminants must be removed.

- SikaBond®-150 Premium Floor adheres without primers and/or activators.

- The subfloor must meet the requirements of national standards, must have good compression and tensile strength and has to be even.

- Defective subfloors shall be treated by taking appropriate measures e.g. grinding, milling, vacuuming or priming.

- To produce an absorbent, even subfloor, a cement- based levelling compound shall be used, e.g. Sika® Level Underlayments or Sika® Level SkimCoat. For appropriate layer thicknesses refer to the relevant valid data sheets.

- Mastic asphalt and other non-absorbent subfloors as well as rubber floor coverings may require specific self-levelling compound layer thicknesses. For appropriate layer thicknesses refer to the relevant valid data sheets.

- Concrete and/or cement screeds must be ground and thoroughly cleaned with an industrial vacuum.

- When installing floor covering with underfloor heating, existing measuring points have to be checked regarding the moisture content of the subfloor.

MIXING

Stir SikaBond®-150 Premium Floor well before use.

CLEANING OF TOOLS

Clean all tools and application equipment immediately after use with water or Sika® TopClean T. Once cured, residual material can only be removed mechanically