SikaBond®-T55

SikaBond®-T55 is a one-component, highly flexible, easy to trowel, low VOC, low odor, moisture cured polyurethane adhesive for full surface bonding of wood flooring. SikaBond®-T55 will tenaciously bond wood to most surfaces, including concrete, plywood, and leveling and patch underlayments that have been properly prepared.

- ~400% elongation

- Bonds unlimited thickness solid and engineered wood

- Low odor

- Easy to trowel

- Fast curing - unfinished wood flooring can be sanded after ~12 hours of cure time

- Crack bridging

- Suitable for most common types of wood floors

- Especially good for problematic woods such as beech and bamboo

- Suitable for bonding wood floors directly onto old ceramic tiles

- Suitable for in-floor radiant heat installation

- Footfall-sound-dampening adhesive

- Contains no water

- Eliminate sleepers and plywood over concrete and gypsum substrates

- Permanently elastic - allows planks to expand and contract without damage to the adhesive or substrate

Usage

SikaBond®-T55 may be used to bond all engineered, solid plank flat milled, shorts, bamboo, cork and parquet hardwood flooring designed by the manufacturer for glue down applications. This adhesive can also be used for many other bonding applications that are common for light commercial and residential applications including acoustic rubber underlayment systems.Advantages

- ~400% elongation

- Bonds unlimited thickness solid and engineered wood

- Low odor

- Easy to trowel

- Fast curing - unfinished wood flooring can be sanded after ~12 hours of cure time

- Crack bridging

- Suitable for most common types of wood floors

- Especially good for problematic woods such as beech and bamboo

- Suitable for bonding wood floors directly onto old ceramic tiles

- Suitable for in-floor radiant heat installation

- Footfall-sound-dampening adhesive

- Contains no water

- Eliminate sleepers and plywood over concrete and gypsum substrates

- Permanently elastic - allows planks to expand and contract without damage to the adhesive or substrate

Packaging

4 gal. (15.14 L) and 5 gal. (18.93 L) pail

Color

Tan

Product Details

ENVIRONMENTAL INFORMATION

| LEED® V4.1 CDPH Standard Method v1.2 | SCAQMD, Rule 1168 | BAAQMD, Reg. 8, Rule 51-226 (20 g/L limit) |

| passes | passes | passes |

Chemical Base

1-component, moisture cured polyurethane

Shelf Life

12 months from the date of production if stored properly

Storage Conditions

The product must be stored in original, unopened and undamaged sealed packaging in dry conditions and protected from direct sunlight at temperatures between 50°F and 77°F (10°C and 25°C).

Density

| ~11.27 lbs/gal (~1.35 kg/L) |

|

Testing

| ~35 | (28 days at 73°F (23°C) and 50% RH) |

Tensile Strength

| ~217 psi (~1.50 MPa) | (28 days at 73°F (23°C) and 50% RH) |

Shear Strength

| ~145 psi (~1.00 MPa), ~1 mm adhesive thickness | (73°F (23°C) and 50% RH) |

Service Temperature

-40°F (-40°C) to 158°F (70°C)

Application

Sag Flow

Consistency: spreads very easily, holds ridges after troweling

Ambient Air Temperature

Room temperature between 60°F (15°C) and 90°F (32°C). For ambient temperatures standard construction guidelines should be followed. Follow all floor covering manufacturers’ acclimation and room temperature requirements.

Relative Air Humidity

Between 40% and 70% during installation is best for adhesive. See floor covering manufacturer for floor covering requirements.

Substrate Temperature

During laying and until SikaBond®-T55 has fully cured, substrate temperature should be greater than 60°F (15°C) and in the case of radiant floor heating, less than 68°F (20°C). For substrate temperatures, standard construction guidelines should be followed.

Substrate Moisture Content

For use as an adhesive only: SikaBond®-T55 is not affected by moisture or vapor transmission. For protection of the floor covering, follow the floor covering manufacturer’s requirements for subfloor moisture. If substrate is not acceptable, use SikaBond®-T55 at recommended coverage rate as Moisture Control or Sika® MB. See Technical Data Sheet for proper instruction.

For use as an adhesive and moisture membrane: Concrete moisture vapor emission rate (MVER) may not exceed 15 lbs. per 1,000 sq.ft. (6.80 kg per 92.9 m2) per 24 hours, anhydrous calcium chloride test (ASTM F1869). Do not install when the relative humidity (RH) of the concrete slab exceeds 90% (ASTM F2170).

Curing Rate

Floor may accept light foot traffic after ~4 hours

Floor can be sanded after ~12 hours

Curing times depend on environmental and subfloor conditions, adhesive layer thickness and floor covering type.

Skin Time / Laying Time

45-60 minutes at 73°F (23°C) and 50% RH

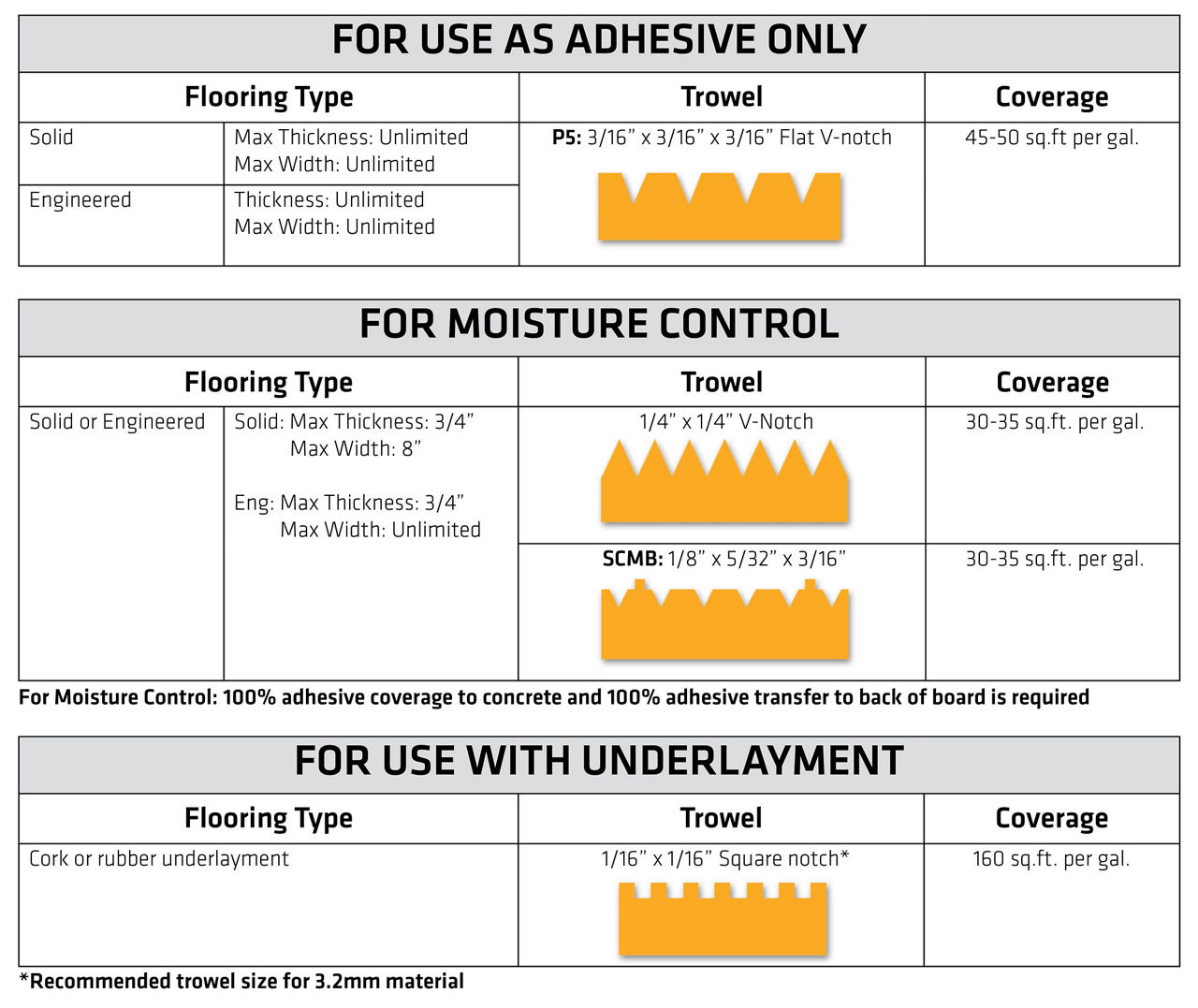

Coverage

- These are estimated spread rate coverages and additional adhesive may be required based on substrate porosity/profile/levelness, wastage or any other variations. Apply product to a test area to calculate the exact coverage for the specific substrate conditions. Trowel diagrams are not to scale.

- Coverage must be monitored to ensure accuracy of application. Trowel angle may prevent proper coverage.

- Installer is responsible for periodic inspection of the trowel to check for excessive wear. Worn trowels must be replaced immediately.

- The above-listed trowels must be used to obtain proper coverage, larger sizes are acceptable. Excessive amounts of adhesive may cause floor covering to slide while placing, check coverage during installation.

- P5 trowels should be used at 90° angle, SC+MB trowel or 1/4 in. (6.3 mm) x 1/4 in. (6.3 mm) V-notch at 45° angle to subfloor to get stated coverages.

- The P5 and SC+MB trowel are available from Sika.

NOTES ON INSTALLATION

These directions are general guidelines for flooring installations. It is the responsibility of the installer to determine proper drying time of the adhesive, trowel size to be used and acceptability of subfloor conditions. All installations must be in accordance with the flooring manufacturer's recommendations. Only flooring that is approved in writing for glue down installations by the flooring manufacturer can be used with SikaBond®-T55. Floors installed with SikaBond®-T55 are not warranted against damage caused by wet mopping, flooding, plumbing leaks or other extraordinary circumstances. For any installation not herein recommended, contact Sika before proceeding.

SUBSTRATE QUALITY

Substrate must be clean and dry, homogeneous, even, free from oil, grease, dust and loose particles. Paint, laitance and other poorly adhering particles must be removed by mechanical means.

Note: Adhesion tests on project specific substrates are recommended to be performed.

SUBSTRATE PREPARATION

- SikaBond®-T55 can be used on properly prepared, structurally sound concrete, cementitious patch/underlayments, chipboards, ceramic tiles, plywood. All floor covering manufacturer’s recommendations must be followed.

- Concrete substrate must have a concrete surface profile of CSP 1-3.

- Thorough examination for excessive moisture in all subfloors is essential. Look around for visible water stains on the drywall and subfloor, particularly on concrete. Checking for and avoiding excessive moisture in every subfloor must be done. Sika requires the use of moisture tests on all concrete and wood subfloors. It is important that the subfloor’s moisture content do not exceed the flooring manufacturer’s or Sika’s recommendations, whichever is lowest. All moisture tests must be documented prior to installation for Sika warranty to be in effect. For on-grade subfloors Sika recommends the use of Sika® MB, Sika® MB Redline or Sika® MB EZ Rapid for best protection against subfloor moisture.

- Below grade applications are generally not recommended unless proper precautions are taken to protect the floor covering from subfloor and in-room humidity extremes.

- A 3,000 psi compressive strength is the minimum requirement needed for SikaBond® wood floor installations, including glue-down wood floors, or glued/mechanically anchored subfloors. Sika products such as Sika® MB, Sika® MB Redline or Sika® MB EZ Rapid can be used on substrates as consolidators to satisfy the minimum psi compressive strength requirements.

- Preparation is a critical step in the installation process and will ensure a successful long term tenacious bond.

- All subfloors must be structurally sound, clean, dry, smooth; free of voids, projections, loose materials, oil, grease, sealers and other surface contaminants. Thoroughly clean with an industrial vacuum. Remove laitance or weak areas mechanically and thoroughly.

- For application over ceramic tiles it is necessary to grind tile surfaces and clean thoroughly with an industrial vacuum.

- When installing floor covering over gypsum based substrates, the gypsum must first be sealed/primed with Sika® MB, Sika® MB Redline or Sika® MB EZ Rapid (see appropriate product data sheet for installation instructions and proper details).

- For substrates with old well bonded non-water soluble adhesive or adhesive residue use Sika® MB, Sika® MB Redline or Sika® MB EZ Rapid – see appropriate product data sheet for installation instructions and proper details. If surface contains asphalt (cutback) adhesive, follow the Resilient Floor Covering Institute “Recommended Work Practices” for removal. When the asphalt (cutback) adhesive is sufficiently removed use the Sika® MB, Sika® MB Redline or Sika® MB EZ Rapid to help promote adhesion to the subfloor or use a Sika® Level patch/level product in conjunction with the correct primer.

- SikaBond®-T55 will adhere to most common patching / levelling compounds. Due to differences in asphalt-based adhesive types and performance capabilities, installer must verify that preparation of the surface is sufficient prior to using Sika® MB or Sika® Level patch / level compound. For unknown substrates, please contact Sika® Technical Services for best practices at 1-800-933-SIKA.

CLEANING OF TOOLS

All tools must be cleaned immediately after use with SikaBond® Remover or standard industry cleaning solvent. Any adhesive that is permitted to cure on the tool will need to be removed by mechanical means. SikaBond® Remover can be used to remove uncured or cured adhesive and fingerprints from wood surface.