CHOOSING THE RIGHT FLOOR FOR YOUR ENVIRONMENT

Each environment has specific criteria that need to be met for the safety and well-being of the patients, visitors and staff, as well as for operational efficiencies and flexibility in space use. A well-designed system can actually improve the quality of care and health outcomes of patients, increase flexibility in space use. A well-designed system can actually improve the quality of care and health outcomes of patients, increase staff productivity lower life cycle costs. If you want help picking the best match for your facility, here are 10 factors to consider when selecting interior finishes for healthcare applications.

HOSPITAL FLOOR SELECTION CRITERIA'S

- Safety

- Aesthetics

- Maintenance

- Comfort

- Sustainability

- Durability

- Resistance

- Cost

- Quality

- References

DOWNLOAD THE GUIDE

Download your digital version of Sika Flooring's 10 Step Guide to Selecting Healthcare Floors.

10 STEPS FOR HEALTHCARE FLOORS:

1. SAFETY

Hundreds of millions of patients globally are affected each year by healthcare associated infections (HAIs). On any given day in the U.S., about 1 in 25 hospital patients has at least one HAI. In 2011, an estimated 75,000 U.S. patients died after contracting an HAI. Research shows that floors often get contaminated by pathogens that can cause HAIs. Ease of cleaning and the ability to prevent growth and transmission of molds, bacteria, and other pathogens are important factors when choosing surface options for healthcare facilities.

In hospitals, slips, trips, and falls are the second most common cause of injuries leading to lost workdays. These incidents may occur from a combination of factors such as floors being wet or patients taking medications that affect their balance. It is important to consider how a floor surface’s slip-resistance properties will hold up throughout its service life. High-tech equipment needs continuous protection from electrostatic discharges, which can cause equipment malfunctions and risk sparking that can result in fires. Therefore, it is important to consider a floor covering’s ability to eliminate or reduce the amount of static electricity in an environment.

2. AESTHETICS

Exposure to daylight. Views of nature and art. A “homey” atmosphere. Research indicates that an aesthetically pleasing environment helps relieve patient stress and increases satisfaction with quality of care.

Floor, wall and ceiling surfaces should support the overall design of a space. Consider materials such as liquid applied products that have inherent flexibility to easily accommodate changes in design schemes, color palettes and operational requirements. Matching floor and wall finishes helps to create a balanced and pleasing design.

3. MAINTENANCE

As discussed in the “Safety” section, infection control and prevention is a critical issue in healthcare facilities. Frequently spilled bodily fluids contain contagious microorganisms. If not cleaned effectively, these substances can be sources of infection (HAIs).

To help minimize and prevent the spread of infection from spills, it is important to select finishes for floors, walls and ceilings that enable effective cleaning. Incompatibility between a cleaning agent and a finish may have an adverse effect on the physical properties of the finish, resulting in unwanted surface changes such as softening or hardening, reduced flexibility, cracking, flaking and discoloring.

The majority of floor failures are related to seams and moisture penetration. A crack or joint failure of just 0.1 mm wide by 1 cm deep by 10 cm long creates a potential reservoir of microorganisms that can hold 140,000 bacteria cells. To put this into perspective, ingesting as few as 10 bacterial cells can make a person ill. Porous surfaces carry an elevated risk of microbiological growths such as molds and fungi. In contrast, non-porous, seamless surfaces are easier to clean and maintain than porous surfaces with joints and seams. Most of all, they do not create environments that are hospitable to microorganisms.

A properly designed and executed cleaning regime is key to maintaining healthy interior finishes. Consider the time and cost of cleaning and maintaining different types of flooring materials. Hard synthetic and mineral surfaces typically require daily dust mopping, regular wet cleaning and periodic deep cleaning. Some hard surfaces such as certain vinyls and linoleums need additional periodic polishing and waxing. Seamless surfaces are typically cleaned in the same way as hard synthetic surfaces but cleaning is more effective due to the lack of seams, which can trap dirt. Soft surfaces such as carpet may require daily vacuuming and periodic wet cleaning with soap and water.

4. COMFORT

Floors, walls and ceilings can have a big impact on patient and staff comfort.

Sound Absorption. Flooring that reduces noise contributes to a quieter environment, which has been linked to improved patient satisfaction.

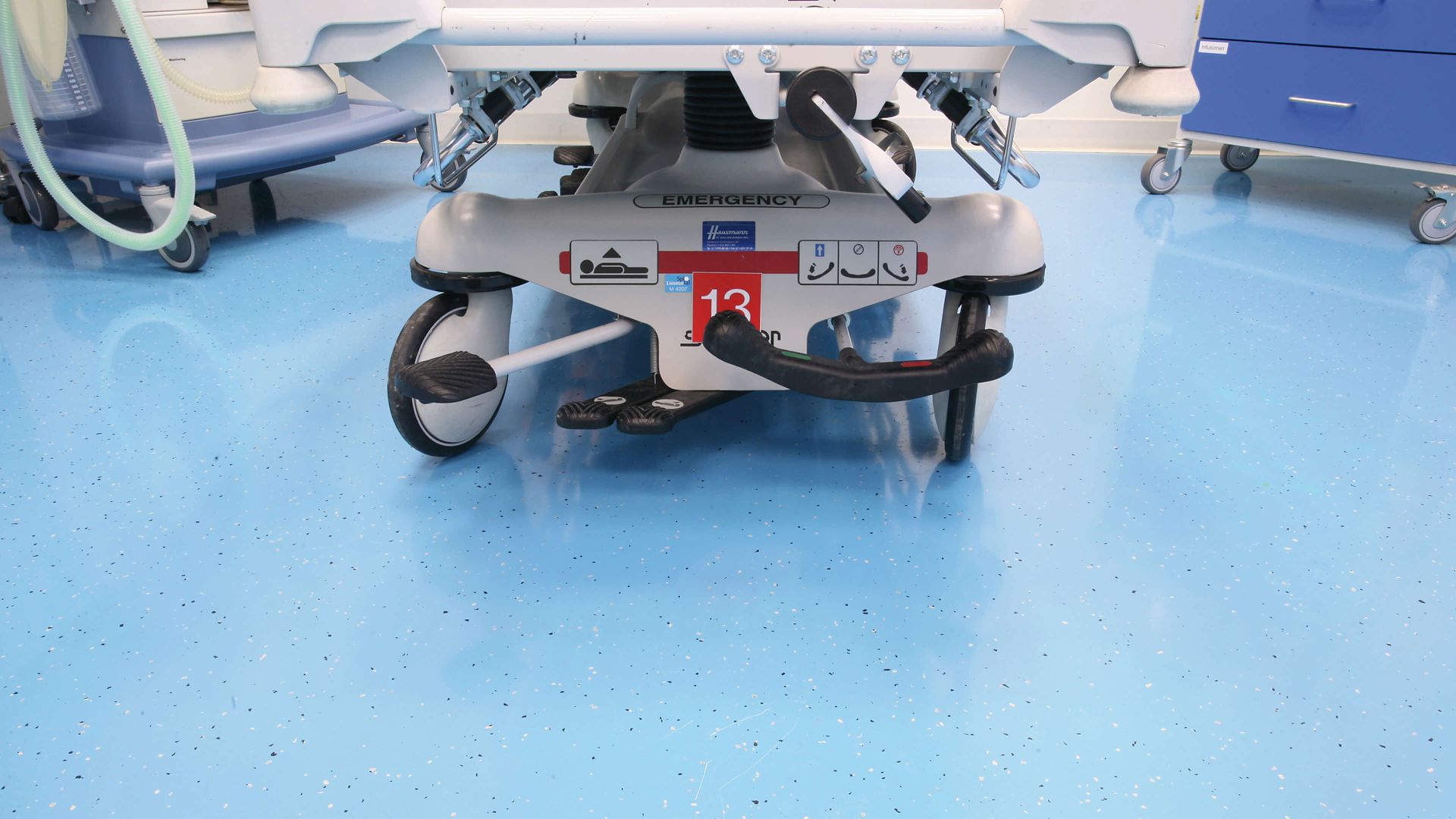

Resiliency. Resiliency refers to a floor covering's ability to spring back after being compressed. Floors with higher resiliency feel soft and comfortable underfoot and help prevent body fatigue but can be more difficult for staff to push hospital beds and other heavy rolling loads over. The right balance, or level of resiliency, should be carefully selected.

Temperature Control. Protection against cold air rising from the floor, or excessive thermal conductivity in the case of under-floor heating, is important to consider when selecting flooring. The product's thermal insulation rating provides accurate information about the product's ability to reduce heat exchange between its surface and the environment. Low thermal conductivity is equated with high insulating capability, adding to the quality of life for patients and staff.

5. SUSTAINABILITY

An important health consideration for floor, wall and ceiling finishes is the volume of volatile organic compounds (VOCs) that materials emit into the interior environment. Products that meet or exceed standards for low VOC emissions contribute to healthier indoor air quality and reduced impact on patients, staff and the environment.

Look for products that comply with the ASTM, EPA Green Globes and low VOC emissions. For liquid architectural coatings and paints, look for compliance with NAHB, EPA and MPI guidelines. Also look for products that have been certified by a third party, internationally recognized and have environmental sustainability standards such as LEED and ISO 14001. ISO 14040:2006 provides a uniform way to measure environmental impact.

Ease of removing dust and particulates from the interior environment may be design criteria for pathology labs, research areas and other critical areas where indoor air pollutants can negatively affect ongoing, critical processes. Look for products that have been certified as Cleanroom Suitable Materials (CSM). CSM is a global standard commonly used in the pharmaceutical industry.

6. DURABILITY

The life expectancy of any surface finish is related to wear. To ensure that a surface continues to look good and perform well over its expected lifespan, choose a product designed to withstand the intended use of the space.

Products with resistance to ultraviolet (UV) radiation have greater color stability and are likely to look better longer than products without UV resistance that are more susceptible to fading. Wall finishes should be flexible enough to withstand expansion, contraction and damage from minor impacts without the need for additional protection. Finishes such as liquid applied coatings allow for walls that are free from joints, crevices and fissures that negatively impact product durability.

7. RESISTANCE

Floor and wall finishes must stand up to the demands of the space for which they are specified. Accidents happen and surfaces with low impact resistance properties are more likely to be damaged.

Hospital beds and other heavy equipment can leave permanent dents in highly resilient flooring, such as rubber or cork surfaces, yet these surfaces may provide shock absorption and protection against further injury in situations when patients fall to the floor. However, these disadvantages may be overcome and the benefits of resiliency resinous flooring industry. Now, softer resins that mitigate sound transfer, have resilient properties and are resistant to chemicals or abrasive environments have been introduced.

Floor surfaces in healthcare facilities are typically exposed to a wide range of stain-producing chemicals such as bodily fluids, hydrogen peroxide, cleaning detergents and sanitizing agents. When specifying floor and wall finishes, consider how effectively each product resists stains and damage from chemicals, as well as its resistance to scrubbing and other mechanical impacts.

8. COST

When judging the capital efficiency of a floor, wall or ceiling surface, it's important to consider hard costs such as the initial costs (including purchase price, delivery and installation) and the costs to maintain the surface over its lifetime and the building's lifetime. Over the life of the facility, the costs of surface maintenance can easily be 10 times higher than the original installation costs. It's also important to consider the impact of the solutions on patient and staff satisfaction, health outcomes, and staff productivity.

It's common for architects, builders and building owners to have different priorities during a construction project. Within the team, the architect may pay the greatest emphasis on aesthetics, and the builder may place the greatest focus on costs. Facility managers are very interested in easy cleaning and maintenance procedures. Different medical teams have different needs for their daily operations. As a facility manager you are responsible for the overall performance and operational costs, which are significantly higher than development or renovation costs.

In the eyes of all stakeholders, working together as a team during a healthcare facility's design phase - whether new construction or renovation - is key to the project's successful outcome. Professional supplier with proven backgrounds in providing high end solutions are a great source of information and can be a valuable partner for your design team.

9. QUALITY

When selecting the interior floor, wall and ceiling solution: Find out if the supplier uses a quality management system such as ISO 9001, which assures uniformity in manufacturing and adherence to a product's published specifications.

Verify that the installation crew has been trained to install your selected product. Look for labels indicating that the product has been independently certified to internationally recognized quality standards. Ask about options that may exist to extend the supplier's quality commitment and assure quality performance over a longer period of time.

10. REFERENCES

Every flooring supplier should be able to provide a list of references. Check them. Additionally, visit installations to see the quality of the job firsthand, to build your trust and confidence in the supplier, and to pick up ideas that may improve your own project.