Use of Stamp Tools

Producing imprinted architectural concrete or cementitious overlay requires skill and practice. Tool selection, pattern layout, tool release type and color, should all be decided well in advance of use.

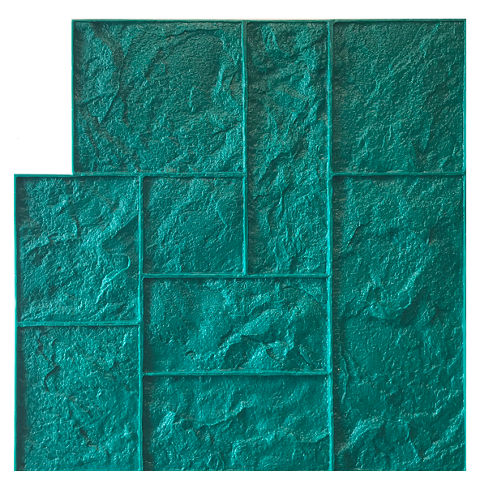

Tool Selection

When resurfacing and imprinting or texturing existing concrete surfaces, SCOFIELD Texturetop Stamp Grade System should be used. SCOFIELD Texturetop Stamp Grade effectively performs at depths from 1/8 inch (3 mm) to 3/8 inch (10 mm), and can be imprinted with LITHOTEX Pavecrafters Professional Grade Imprinting Tools that have a profile depth that is half or less of the application thickness.

Layout Considerations:

Since the size of each Pavecrafters tool will vary depending on the texture and pattern, the layout should be determined for each area to be imprinted. Area dimensions and tool placement should be planned to produce an optimum appearance from the specified pattern.

Areas to be imprinted must be designed so that their dimensions are in multiples of those of the imprinting tools plus approximately 1/16 inch (2 mm) per tool to allow for movement during imprinting. Since variations occur in straightness, pattern placement should not directly follow walls, but start at the form lines.

Imprinting installations normally follow straight lines, even when the substrate concrete does not, as often happens when imprinting curved walks and drives. When possible, place patterns to avoid looking down long grout or joint lines, making minor straight-line placement errors more noticeable. The best appearance will be obtained if long grout or joint lines are at an angle to the primary line of sight.

Elements that break or interfere with the pattern such as columns, walls, steps, planters, and drains should be considered and their placement or the pattern placement planned so that natural stopping points are formed. When possible, construction joints should be placed so that they are masked in the pattern, usually along pattern grout lines or boundaries.

Predetermined measuring points should be included in the plans or drawings for use in the initial alignment of the pattern and to check alignment accuracy as imprinting proceeds.

Tool Use

The stamping of cementitious materials should take place after all bleed water has been reabsorbed into the substrate, it is still plastic, can be moved with moderate finger pressure, and is still easily imprinted. The careful timing of each step, and repeatedly using a single technique, is important to develop consistent results. If colored release is used, application to younger more plastic concrete will embed more color into the surface, and stamping material in a later state of cure will embed less color. Timing will be influenced by temperature and humidity conditions. Always prove timing and stamping technique as described in the Jobsite Test Sections portion of this document.

Jobsite Test Sections and Samples

Prior to general jobsite use, a representative Jobsite Test Section(s) or “Mock-Ups” must be produced and approved for each individual concrete color mix design, imprinting pattern, surface finish/texture, and for each curing compound/sealer and coating combination that will be created. They must be of adequate size to be representative of the job, and utilize the same workers that will perform the final installation. For large stamp patterns utilizing multiple imprinting matts, a minimum of 100 square feet (10m2) is required. Careful attention should be paid to edge pattern terminations, and pattern rotation techniques.

Producing antiqued, imprinted concrete requires skill and practice. Timing, finishing, application and removal techniques, mix design, texture of the imprinted pattern, color combinations, weather, experience in use of the materials, sealing and other factors will significantly affect the final appearance of the surface. Construct the Jobsite Test Section in conditions as similar as possible to those expected during the larger installation.

When applicable, test completed systems for wet and dry slip resistance. Evaluate polishing or coating application techniques, final color, and visual appearance. Do not proceed with products, techniques, or finishing systems that do not meet required specifications or meet with site owner approval.

Cleaning

Clean tools with warm water and mild detergent after use. Store in dry conditions to avoid mold and mildew.