DriTac® 7200 Edge

DriTac 7200 Edge is a contractor grade, urethane wood flooring adhesive that is very easy to spread, allowing for increased productivity.

• Freeze-Thaw Stable

• Non-Slumping

• Low Odor

• MVER up to 5 lbs./80% RH

• Remains Elastomeric

• Easy to Clean When Wet

• Helps Contribute to LEED Credits

Usage

• Multi-Ply Engineered Plank• Bamboo

• Plywood

• Parquet

• Solid Planks

• Exotic Woods

• Acrylic Impregnated Wood

• Recycled Rubber Flooring

• Cork/Rubber/Foam Underlayment

Advantages

• Easy to Spread• Freeze-Thaw Stable

• Non-Slumping

• Low Odor

• MVER up to 5 lbs./80% RH

• Remains Elastomeric

• Easy to Clean When Wet

• Helps Contribute to LEED Credits

Packaging

4 gal. (15.14 L)

Product Details

Shelf Life

12 months when stored at 75° F and 50% relative humidity.

Storage Conditions

Store in undamaged original sealed containers, in dry conditions and protected from direct sunlight at temperatures between 50 °F and 77 °F (10–25 °C)

Application

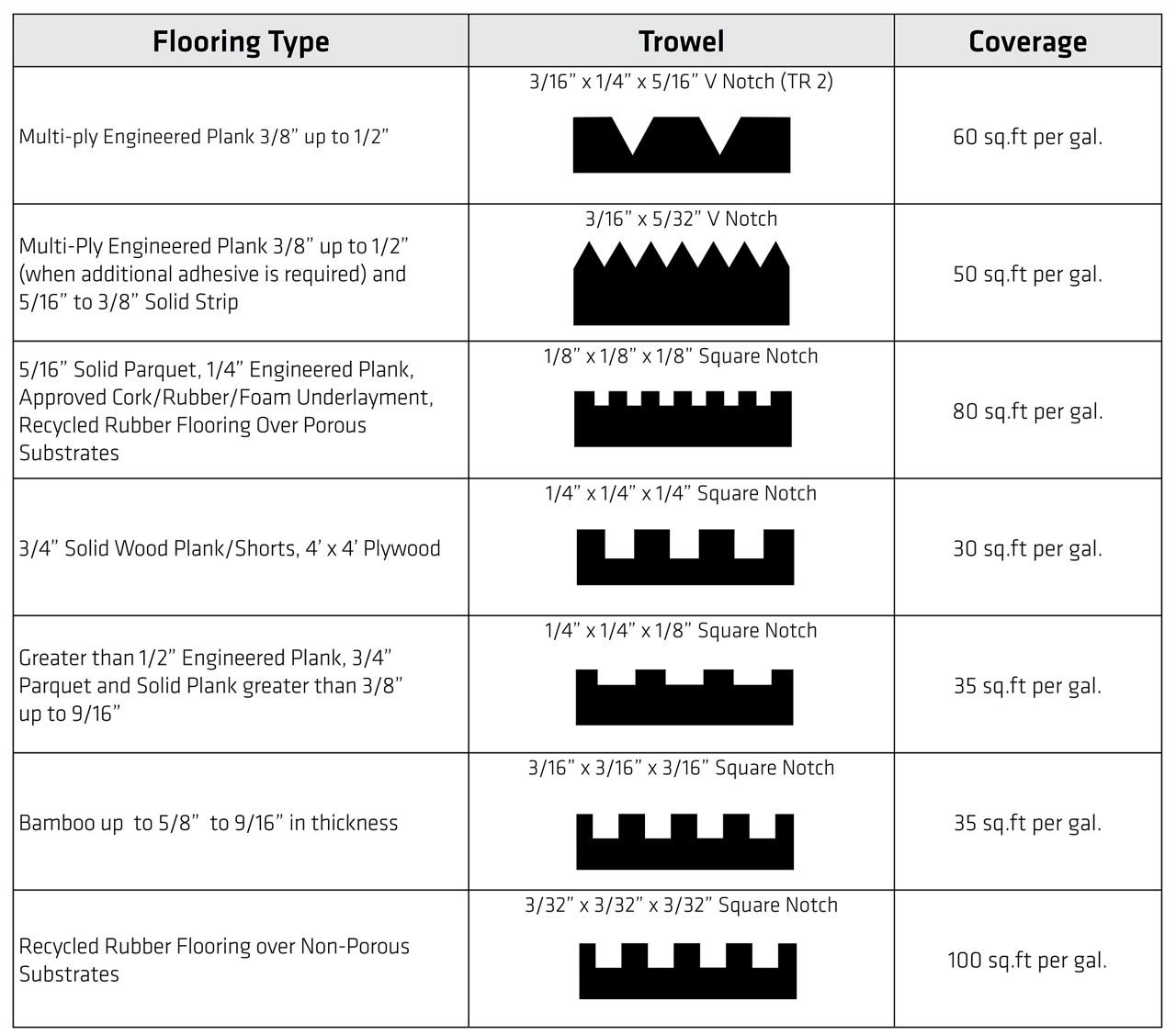

Coverage

APPLICATION INSTRUCTIONS

GENERAL CHARACTERISTICS

DriTac 7200 has been formulated for the interior installation of multi-ply engineered plank, solid plank, exotic wood, acrylic impregnated wood, parquet, plywood, recycled rubber flooring and cork and rubber underlayments over approved substrates. DriTac 7200 is moisture resistant, however, to prevent damage to the flooring from subfloor moisture, carefully follow the wood manufacturer’s instructions. The time it takes for the adhesive to cure is related to temperature, humidity, porosity of the subfloor, ventilation and air movement.

APPROVED SUBFLOORS

Applies for Adhesive Bond Only:

• Plywood

• Terrazzo and ceramic tile

• Underlayment grade O.S.B.

• Vinyl tile flooring coated with vinyl primer

• Non-cushioned fully adhered sheet vinyl coated with vinyl primer

• Concrete; above, on or below grade in the absence of excessive moisture and alkalinity

• Light weight concrete/gypcrete (coated with latex primer), per ASTM F2419

Note: If Sika-DriTac’s list of approved subfloors is different from the flooring manufacturer, Sika-DriTac requires that you must follow the flooring manufacturers recommendation.

SUBFLOOR REQUIREMENTS

Applies for Adhesive Bond Only:

Clean - It is required that all concrete, sheet vinyl, vinyl tile, terrazzo and ceramic tile sub floors be scoured by mechanical means to remove dirt or any surface contamination such as paint, grease, oil, sealers, waxes, curing compounds and glass-like concrete. DriTac 7200 adhesive should not be used over these substances. Sweep or vacuum the subfloor before installation.

Preparation - All floors should be flat to within 3/16” in 10 ft. or 1/8” in 6 ft. Not properly flattening the substrate to industry standards can allow moisture to adversely affect the wood flooring and is not covered by the substrate moisture warranty.

Smooth and Flat - Remove any high spots by mechanical means and fill any low spots with a good quality cementitiousbased latex patch mix.

CONCRETE SUBFLOORS

Concrete should be at least 60 days old. Inspect the concrete before installing flooring over it. First inspect for any wetness at the base of the drywall or for visible signs of moisture on the concrete. Second, test for moisture. Use a Calcium Chloride Method Test or Relative Humidity Test for reliable concrete testing. The results should not exceed 5 lbs., per 1,000 square feet over 24 hours, per the ASTM F1869 Calcium Chloride Method Test, or 80% Relative Humidity (RH), per the ASTM F2170 Relative Humidity Method Test. The maximum reading on concrete for wood installations should not exceed the wood flooring manufacturer’s recommendations. Many wood flooring products can be installed over lightweight concrete (less then 3000 PSI) or gypcrete, providing the surface is properly prepared. Follow the concrete manufacturer’s recommendation for the application of a surface hardener/sealer. Radiant heated subfloors should be turned off 24 hours prior to and during installation to prevent premature curing of the adhesive.

SHEET VINYL, VINYL TILE, TERRAZZO SUBFLOORS

All tiles or sheet goods must be firmly bonded to the subfloor. Make certain the sheet vinyl is a full spread system, perimeter installations are unacceptable. If materials are poorly bonded to the subfloor remove them down to the original subfloor and sand or scrape off all traces of old adhesive. Do not glue over heavy cushioned (1/4”) sheet goods or rubber tile. New sheet vinyl or vinyl tile must be coated with a primer. Old vinyl must be sanded first, then cleaned with Trisodiumphosphate (TSP) or equivalent cleaner to remove all wax and other coatings. CAUTION: Sanding or removing tile flooring containing asbestos is a health hazard. If there is any doubt concerning the contents, professional advice should be sought. Asbestos has been labeled a carcinogen.

PLYWOOD, ORIENTED STRAND BOARD (OSB) OR WOOD SUBFLOORS

Before installing over any one of these subfloors, test for moisture using a reliable moisture meter such as the Tramex Wood Moisture Meter or equivalent. The moisture content should not exceed 12%. If it is over 12%, either wait until the subfloor is drier or stabilize the subfloor with an additional layer of ¼” plywood. All joints in subflooring materials should have 1/8” expansion space around all panels. If expansion space is not present, cut around and through the panel joints with a circular saw. When installing a plywood sheet subfloor over concrete, use a ¼” x ¼” x ¼” square notched trowel to apply adhesive. Score 3/8” deep every 8 to 10 inches on 4’ x 4’ sheets of ¾” exterior. Set 4’ x 4’ sheets into wet adhesive. Apply weight as necessary and allow to cure overnight.

CAUTION: Subfloors with high moisture content may shrink at a later date causing cracks to appear in the wood floor.

WOOD INSTALLATIONS

For best results, tip the pail carefully to dispense adhesive. Provide adequate ventilation and air movement. Ideally, installation should not begin until all wet work (painting, dry wall materials, etc.) is complete and the heating/air conditioning system is in operation. Jobsite temperature should be between 55 and 90 degrees Fahrenheit. Trowel only the amount of adhesive that can be covered in 30 minutes. Install wood flooring into wet adhesive only. Secure the first row with edge blocking or top nail with finishing or sprig nails. Tighten side and end joints and reduce scooting by securing the flooring together with a manufacturer-approved method (painters tape, side blocking, strapping, etc.). Occasionally check for transfer to back of wood flooring. If adhesive transfer is less than 90% to the back of the plank scrape up the adhesive and apply fresh DriTac 7200. Apply weight to any bowed flooring and all floor mounted trim moldings. Remove all defective or unsightly boards immediately. The adhesive is very tenacious and flooring is difficult to remove after the adhesive has cured. Roll the floor with a 100 lb. roller every two to three hours during and immediately after installation.

RECYCLED RUBBER FLOORING INSTALLATIONS

This product is approved for installing all recycled rubber flooring products that are recommended for installation with a moisture cure urethane adhesive. Check with the flooring manufacturer for installation recommendations.

APPROVED CORK/RUBBER/FOAM UNDERLAYMENT INSTALLATIONS

• Cut underlayment to length and lay loosely over the area to be installed. Both ends of the roll must curl down towards the subfloor. If the ends curl up, turn the underlayment over.

• Pull the loose laid material back at least half the length of the roll. Using the recommended trowel, apply DriTac 7200 to the subfloor. Place underlayment into adhesive utilizing wet-lay method. Upon placing underlayment into the adhesive, roll both ways with a 100 lb roller. Repeat the installation for the other half of the subfloor, insuring all joints are butted together tightly.

• Allow adhesive to set prior to proceeding to flooring installation. It is highly recommended to allow at least 18 hours prior to installation of the flooring.

NAIL ASSIST INSTALLATIONS

This adhesive can be used for nail assist installations, when recommended in writing by the wood flooring manufacturer.

PRECAUTIONS

• Contains Methylene Diphenyl Diisocyanate. May cause skin and/or eye irritation. May cause dermatitis and allergic responses. Potential skin and/or respiratory sensitizer. Inhalation of vapors may cause irritation and intoxication with headaches, dizziness, and nausea. See Safety Data Sheets for further information. Ingestion may cause irritation.

• KEEP OUT OF REACH OF CHILDREN. Avoid contact with skin, eyes and clothing. Wash thoroughly after handling. Avoid breathing vapors. Use only with adequate ventilation. Use impervious gloves, eye protection and if TLV is exceeded or if used in a poorly ventilated area, use NIOSH/MSMA approved respiratory protection in accordance with applicable federal, state and local regulations. DO NOT take internally. Empty container may contain hazardous residues.

FIRST AID

In case of eye contact, flush thoroughly with water for at least 15 minutes. SEEK IMMEDIATE MEDICAL ATTENTION. In case of skin contact, wash affected areas with soap and water. If irritation persists, SEEK MEDICAL ATTENTION. Remove and wash all contaminated clothing. If inhalation causes physical discomfort, move to fresh air. If discomfort persists, SEEK MEDICAL ATTENTION.

REUSE OF PARTIAL CONTAINERS

Cover adhesive in the pail with a plastic trash bag or two layers of plastic film. Put lid on tightly. Turn over pail. This will seal contents from outside air. To open container, take off lid, cut plastic and remove thin layer of cured adhesive on surface.

INSTALLER RESPONSIBILITY

These directions are general guidelines for flooring installations. It is the responsibility of the installer to determine proper drying time of the adhesive, trowel size to be used and acceptability of subfloor conditions. Installations must also be in accordance with flooring manufacturers recommendations. Only flooring that is approved for glue down installations by the flooring manufacturer can be used with DriTac 7200. Floors installed with DriTac 7200 are not warranted against damage caused by wet mopping, flooding, plumbing leaks or other extraordinary circumstances. For any installation not herein recommended, contact DriTac Flooring Products before proceeding.

CLEANING OF TOOLS

• Remove excess urethane adhesive as soon as possible before it dries on the flooring surface. Clean up as you go. Cured urethane adhesive is very difficult to remove.

• Never attempt to remove DriTac 7200adhesive from tools or flooring with water as this will cause the adhesive to cure more rapidly.

• Remove residue before it dries with flooring manufacturer-approved cleaning method.

• Clean DriTac 7200 adhesive from floor and tools while still wet with flooring manufacturer-approved cleaning method.