SikaBond®-5800

SikaBond-5800 (formerly DriTac 5800 ToughBond) is a premium resilient flooring adhesive that is solvent-free with very low odor.

• High Shear and Peel Strength

• Excellent Bond Strength

• High Moisture Resistance - Up to 12 lbs/99% RH

• Very Low Odor

• Spreads Easily with Easy Clean Up

• Helps Contribute to LEED Credits

Usage

• Luxury Vinyl Tile/Plank• Carpet Tile

• Rubber Flooring

• Cork/Rubber/Foam Underlayment

• Fiberglass Backed Sheet Vinyl

• Vinyl Sheet Goods

• Cork Tile

Advantages

• High Initial Tack• High Shear and Peel Strength

• Excellent Bond Strength

• High Moisture Resistance - Up to 12 lbs/99% RH

• Very Low Odor

• Spreads Easily with Easy Clean Up

• Helps Contribute to LEED Credits

Packaging

• 4-Gallon Pail

• 1-Gallon Pail

Product Details

Shelf Life

24 months in original unopened packaging

Storage Conditions

+41°F (+5°C) to +77°F (+25°C) The product must be stored in original, unopened and undamaged sealed packaging in dry conditions

Application

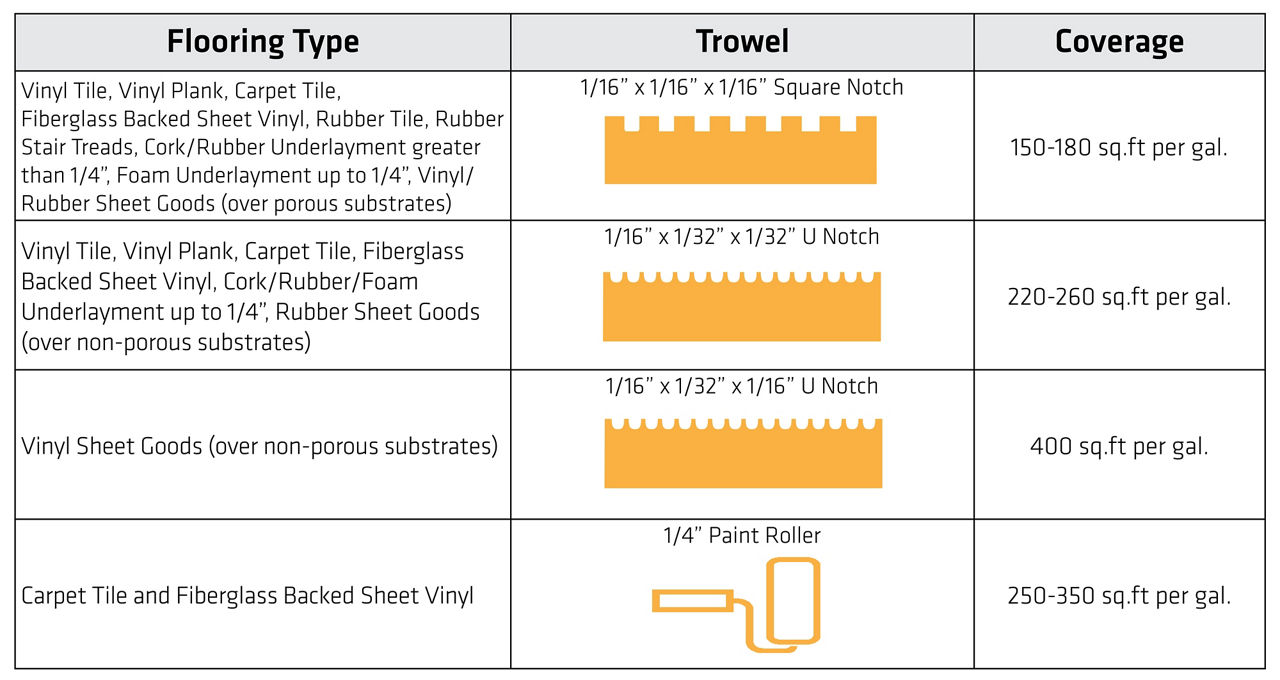

Coverage

APPLICATION INSTRUCTIONS

GENERAL CHARACTERISTICS

SikaBond-5800 has been formulated for the interior installation of luxury vinyl tile (LVT), luxury vinyl plank (LVP), vinyl sheet goods (homogeneous/heterogeneous), fiberglass backed sheet vinyl, carpet tile, rubber flooring and cork/rubber/foam underlayments over approved substrates. SikaBond-5800 offers maximum bond strength, high moisture resistance and can be roller or trowel applied. Flooring must be approved in writing by manufacturer for glue down installations. Flooring may be installed up to 3 hours after initial drying if the area remains dust and dirt free. SikaBond-5800 helps control vinyl plank shrinkage in controlled environments and is a solvent-free adhesive with very low odor.

APPROVED SUBFLOORS

A.P.A. Rated Plywood (exterior or underlayment grade); Existing vinyl tile flooring; Concrete - above or on grade; Terrazzo; Underlayment grade O.S.B.; Lightweight concrete/gypcrete (coated with latex primer), per ASTM F2419; Existing fully adhered, non-cushioned sheet vinyl; Below-grade concrete in the absence of excessive moisture and alkalinity (Use below-grade only when recommended by flooring manufacturer). Sika does not approve using SikaBond-5800 over ceramic tile. Note: If Sika’s list of approved subfloors is different from the flooring manufacturer, Sika requires that you must follow the flooring manufacturer’s recommendation.

SUBFLOOR REQUIREMENTS

• All subfloors must be smooth, sound, dry, clean, flat and free of dirt, grease, wax, paint, oil or anything that would hinder a good bond, per ASTM F710.

• Trisodiumphosphate (TSP) can be used to clean vinyl surfaces. Concrete subfloors not meeting this standard must have contaminants removed by mechanical means, then vacuumed clean. Check with the flooring manufacturer for installation recommendations.

• Do not install over old “cutback” petroleum adhesives. These must be removed completely or covered with a portland cement leveling compound.

• When installing flooring over gypsum based levelers, the gypsum must first be sealed/primed and allowed to dry prior to installation of flooring (see gypsum manufacturer’s instructions for recommended sealer/primer).

• Complete drying of leveling compounds is critical before installation. While curing time may only take a few hours, the complete drying time of these compounds can take 24 hours or more. Please follow manufacturer’s instructions.

• Epoxy and poured vapor barriers may leave an oily residue after application, which should be removed. The vapor barrier’s surface should be abraded or lightly sanded and cleaned thoroughly. When installing over a non-porous subfloor, additional flash-off is needed.

• When using new sheet vinyl as a moisture barrier over concrete, a vinyl primer must be applied. Refer to manufacturer’s instructions and limitations.

• If there is a concern about adhesion to any subfloor, install a test area before installing the entire floor.

• Subfloors must be flat to 3/16” in a 10’ radius or 1/8” within a 6’ radius.

• Remove any high spots by mechanical means and fill any low spots with a good quality cementitious-based latex patch mix.

• Thorough examination for excessive moisture in all subfloors is essential.

• Look around for visible water stains on the drywall and subfloor, particularly on concrete. Sika does not warrant the installation of Sika adhesives over non-approved concrete sealers and coatings. For more information contact Sika.

• Checking for and avoiding excessive moisture in every subfloor must be done. Sika requires the use of moisture tests on all concrete and wood subfloors. It is important that the subfloor’s moisture readings do not exceed the flooring manufacturer’s or Sika’s recommendations, whichever is lowest. If excessive moisture is present, use an appropriate vapor barrier. All moisture tests must be documented prior to installation for Sika warranty to be in effect. After moisture testing of the concrete subfloor is complete, if moisture is above limitations, a Concrete Moisture Control System is required. For more information, contact Sika at (201) 933-8800.

• The maximum level for moisture emission when installing approved resilient flooring is 12 lbs. per 1,000 square feet over 24 hours, per the ASTM F1869 Calcium Chloride Method Test and up to 99% Relative Humidity (RH), per the ASTM F2170 Relative Humidity Test.

• The maximum level for moisture emission when installing vinyl sheet goods is 5 lbs. per 1,000 square feet over 24 hours, per the ASTM F1869 Calcium Chloride Method Test and up to 80% Relative Humidity (RH), per the ASTM F2170 Relative Humidity Test.

• Moisture in wood subfloors should be measured with a wood moisture meter. The moisture content should not exceed 12%. Read flooring manufacturer’s moisture standards. Follow the instructions carefully.

• Radiant heated subfloors should be turned off 24 hours prior to, during and after installation to prevent premature curing of the adhesive.

• Jobsite Information, Conditions and Acclimation: The adhesive, floor covering and area to receive flooring must be maintained at a temperature of 65°-95°F and at a relative humidity of 35%-65% for 72 hours before, during and after installation.

• Special Instructions: Existing concrete must meet applicable standards and specifications. ASTM E1745 specification for a plastic moisture vapor retarder must be installed below the concrete. The concrete must be fully cured, (a minimum of 45 days) no signs of visible moisture and free from hydrostatic pressure. SikaBond-5800 is a high-moisture tolerant pressure sensitive adhesive, however, it does not form a moisture barrier and is not considered a sealer. SikaBond-5800 will not protect the flooring from moisture damage. Refer to flooring manufacturer’s recommendations for moisture limitations.

LUXURY VINYL TILE & LUXURY VINYL PLANK FLOORING INSTALLATIONS

All LVT and LVP flooring must be dimensionally stable. Porous Surfaces: May be used as a wet-lay method or a pressure sensitive adhesive over porous surfaces. To use wet, apply adhesive with the recommended trowel and allow to flashoff for 10-15 minutes before installing flooring. Lay tile or plank into wet adhesive according to flooring manufacturer’s instructions. Adhesive must transfer to floor product to ensure proper bond. For wet-lay installations, please wait 8 hours before allowing traffic. To use as a pressure sensitive adhesive, allow the adhesive to dry to a tacky state and then install flooring according to flooring manufacturer’s instructions. Non-Porous Surfaces: Apply adhesive with the recommended trowel and allow to dry completely. Lay in the tile or plank according to the flooring manufacturer’s instructions. The highly aggressive pressure sensitive grip prevents slippage and minimizes seam gaps. Drying time is 45-60 minutes and will vary depending on temperature and humidity. Installation over areas of incomplete drying can result in job failure. For flash-off

installations, traffic can begin immediately.

VINYL SHEET GOODS (HOMOGENOUS/HETEROGENOUS) & RUBBER FLOORING INSTALLATIONS

Porous Surfaces: May be used either wet or as a pressure sensitive adhesive over porous surfaces. To use wet, apply adhesive with the recommended trowel and allow to flash-off for 10-15 minutes before installing flooring. Lay tile, plank or sheet goods into wet adhesive according to flooring manufacturer’s instructions. Adhesive must transfer to flooring product to ensure proper bond. To use as a pressure sensitive adhesive, dry to a tacky state and then install flooring according to flooring manufacturer’s instructions within 3 hours. Non-Porous Surfaces: Apply with the recommended trowel. When installing sheet goods over non-porous surfaces, SikaBond-5800 adhesive must be utilized as a pressure sensitive adhesive for permanent bond only. Time required will vary with ambient conditions.

FIBERGLASS BACKED SHEET VINYL INSTALLATIONS

• Apply adhesive with recommended roller to approved substrate. It is the installer’s responsibility to apply the proper amount of adhesive for the job condition.

• Allow adhesive to completely dry until it will not transfer to the fingers when pressed.

• Lay flooring according to manufacturer’s recommendations.

• For permanent installations, (over porous substrates only) install fiberglass backed sheet vinyl into the wet adhesive.

• Complete the job by using the “Broom Method” or installer’s choice for removing air pockets.

NOTE: Restrict heavy traffic on floor for 24 hours after installation.

CARPET TILE INSTALLATIONS

• Used “dry,” it is a releasable and rebondable pressure sensitive adhesive for vinyl backed carpet tiles. For a releasable bond, SikaBond-5800 may be applied to porous or non-porous surfaces and allowed to dry “tacky.” Tiles may be removed as needed to change the pattern or to replace worn tiles.

• When used “wet” the water in the adhesive must have an avenue of escape (one surface must be porous) and the bond created will be permanent.

• Install flooring according to manufacturer’s recommendations.

CORK TILE INSTALLATIONS

• Check with cork manufacturer for moisture testing, acclimation and other special installation instructions.

• Area to receive flooring should always acclimate to “live-in” temperature and humidity conditions.

• When installing cork flooring using SikaBond-5800, the adhesive must be used as a contact adhesive. Begin by spreading SikaBond-5800 on the subfloor using the appropriate trowel and allow the adhesive to completely dry. Ensuring the adhesive is thoroughly dry will help prevent moisture being transferred to the tile. Drying time will vary with the temperature and humidity conditions. After the adhesive has thoroughly dried on the sub floor apply a thin coat of adhesive to the back of the cork tiles using a paint bush or paint roller. Allow adhesive on the back of the cork to flash for approximately 15 minutes before installing the tiles. Roll the flooring during and immediately after installation. Allow for recommended expansion space.

APPROVED CORK/RUBBER/FOAM UNDERLAYMENT INSTALLATIONS

• Cut underlayment to length and lay loosely over the area to be installed. Both ends of the roll must curl down towards the subfloor, if they curl up, turn the underlayment over.

• Pull the loose laid material back at least half the length of the roll. Using the recommended trowel apply SikaBond-5800 to the subfloor. Allow SikaBond-5800 to flash for 20-30 minutes prior to placing underlayment into adhesive. Upon placing underlayment into the adhesive, roll both ways with a 100 lb roller. Repeat the installation for the other half of the subfloor, insuring all joints are butted together tightly.

• Allow adhesive to set prior to proceeding to flooring installation. It is highly recommended to allow at least 18 hours prior to installation of the flooring.

VENTILATION

Installers should provide adequate cross-ventilation during and for 24 hours after installation.

FREEZE-THAW STABILITY

While this adhesive is freeze-thaw stable, per ASTM D-7149, it should be protected from freezing during transit and storage.

PRECAUTIONS

V.O.C. 0 grams/liter. Avoid eye contact. In case of eye contact, flush eye with clean water for fifteen minutes. If irritation persists, get medical attention. Use with adequate ventilation. Keep out of reach of children. See Safety Data Sheet for further information.

FIRST AID

In case of eye contact, flush thoroughly with water for at least 15 minutes. SEEK IMMEDIATE MEDICAL ATTENTION. In case of skin contact, wash affected areas with soap and water. If irritation persists, SEEK MEDICAL ATTENTION. Remove and wash all contaminated clothing. If inhalation causes physical discomfort, move to fresh air. If discomfort persists, SEEK MEDICAL ATTENTION.

CLEANING OF TOOLS

Wet adhesive can be removed with a damp cloth. Dried SikaBond-5800 can be removed with mineral spirits or a safe solvent. Hands and tools may be cleaned with “waterless hand cleanser” available at hardware and auto supply stores.

FAQ

SikaBond®-5800 has a shelf life of 24 months when stored in its original, unopened packaging. It should be kept in dry conditions and stored between 41°F (+5°C) and 77°F (+25°C) to ensure maximum effectiveness. Avoid exposing the adhesive to freezing temperatures during transport and storage, even though it is freeze-thaw stable per ASTM D-7149.

SikaBond®-5800 has high moisture resistance and can be used on below-grade subfloors if moisture levels are within acceptable limits. However, it does not act as a moisture barrier. For concrete subfloors with excessive moisture, it is crucial to use a vapor barrier in accordance with the flooring manufacturer's recommendations. Always test for moisture levels and consult the manufacturer if you're unsure about using it in moisture-prone areas.

The waiting time before walking on the floor depends on the type of flooring and installation method. For most installations, including LVT, LVP, and vinyl sheet goods, you should allow at least 8 hours before allowing foot traffic if using a wet-lay method. For pressure-sensitive applications, traffic can begin immediately after installation, but it is recommended to avoid heavy traffic for at least 24 hours to allow the adhesive to set properly.

SikaBond-5800 is a high-performance, polyurethane-based resilient flooring adhesive used for bonding to a wide range of materials, including wood, metal, ceramic, concrete, and various types of plastic. It is commonly used in construction, flooring, and DIY applications where strong and durable adhesion is needed.

The maximum allowable moisture level in concrete subfloors is 12 lbs. per 1,000 square feet over 24 hours (measured using the ASTM F1869 Calcium Chloride Method Test) and up to 99% relative humidity (RH) (measured using the ASTM F2170 Relative Humidity Test). For vinyl sheet goods, the moisture level must not exceed 5 lbs. per 1,000 square feet over 24 hours.

If the adhesive dries too quickly, it may not bond properly. Ensure you are applying the adhesive in the recommended temperature and humidity conditions (65°F to 95°F and 35%-65% RH). For certain flooring types, such as LVT or LVP, you can use SikaBond®-5800 either as a wet adhesive (allowing a 10-15 minute flash-off time) or as a pressure-sensitive adhesive (dry to a tacky state). Ensure that you are working within the time frame before the adhesive becomes too dry for proper bonding.

No, SikaBond®-5800 is compatible with approved subfloors such as A.P.A. Rated Plywood, concrete, terrazzo, existing vinyl tile flooring, underlayment grade OSB, and lightweight concrete or gypcrete. It is not approved for use over ceramic tile or certain non-porous surfaces Always check with the flooring manufacturer for recommendations and ensure the subfloor is clean, smooth, dry, and free from contaminants.

SikaBond®-5800 is suitable for installing a variety of resilient flooring types, including Luxury Vinyl Tile (LVT), Luxury Vinyl Plank (LVP), carpet tile, rubber flooring, cork/rubber/foam underlayment, fiberglass-backed sheet vinyl, and cork tiles.