DriTac® 9100 Contractor's Choice

DriTac 9100 Contractor’s Choice is a contractor grade, polymeric resin wood flooring adhesive formulated for wet-lay installations. Installers must lay wood into the adhesive immediately after troweling.

• High Solids

• Contractor Grade

• Easy Clean Up

• Spreads Easily

• Non-Slumping Formula

• Nonflammable

• No Flash Time - Wet-Lay Installation

• Helps Contribute to LEED CreditsEASY

Usage

• 3/4” Solid Shorts• Plain-Back Parquet

• Multi-Ply Engineered Plank

• Acrylic Impregnated Plain-Back Parquet

• Acrylic Impregnated Multi-Ply Engineered Plank

Advantages

• Low Odor• High Solids

• Contractor Grade

• Easy Clean Up

• Spreads Easily

• Non-Slumping Formula

• Nonflammable

• No Flash Time - Wet-Lay Installation

• Helps Contribute to LEED CreditsEASY

Packaging

4 gal. (15.14 L)

Product Details

Shelf Life

12 months when stored at 75° F and 50% relative humidity.

Storage Conditions

Store in undamaged original sealed containers, in dry conditions and protected from direct sunlight at temperatures between 50 °F and 77 °F (10–25 °C)

Application

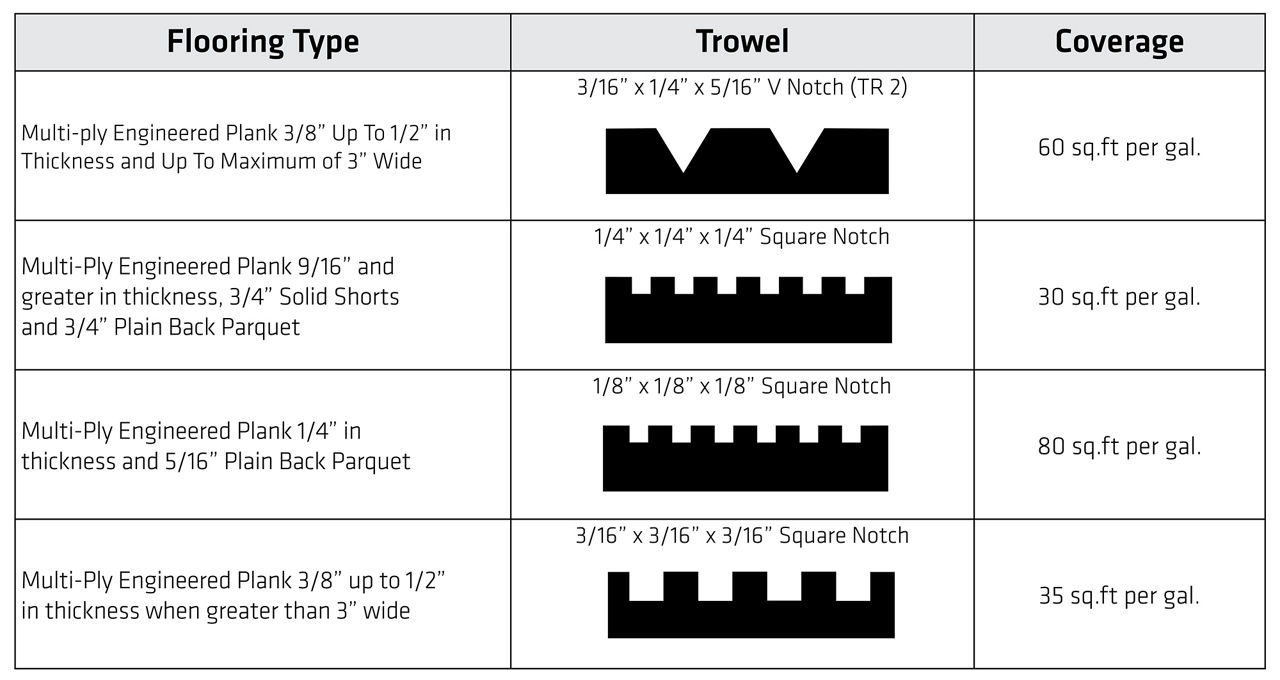

Coverage

APPLICATION INSTRUCTIONS

GENERAL CHARACTERISTICS

DriTac 9100 has been formulated for the interior installation of multi-ply engineered plank, plain-back parquet (not foam back), 3/4” solid shorts, acrylic impregnated multi-ply engineered plank and acrylic impregnated plain-back parquet. over approved substrates. Do not use DriTac 9100 Contractors Choice for installing bamboo, beech, teak, foam-backed wood, cork flooring or oily woods.

APPROVED SUBFLOORS

• Concrete, above or on grade in the absence of moisture

• Do not use below-grade

• A.P.A. standard underlayment particle board

• Underlayment grade plywood

• Substrates prepared with cementitious leveling compounds

• Underlayment grade O.S.B.

• Do not use DriTac 9100 over ceramic tile and vinyl

SUBFLOOR REQUIREMENTS

• When installing over existing hard surface floors, remove finish to allow a good mechanical bond.

• Subfloor must be sound, smooth, dry and clean: free of dirt, wax, grease, loose paint, or any foreign matter that would interfere with a good bond.

• Complete drying of leveling compounds is critical before installation. While curing time may only take a few hours, the complete drying time of these compounds can take 24 hours or more. Please read manufacturer’s instructions.

• Radiant-heated subfloors - DO NOT USE DriTac 9100.

• If there is a concern about adhesion to any subfloor, install a test area before installing the entire floor.

• Subfloors must be flat to within 3/16” in a 10’ radius or 1/8” within a 6’ radius.

• Remove any high spots with a terrazzo grinder or sander and fill any low spots with a good quality cementitious based latex patch mix.

• Thorough examination for excessive moisture in all subfloors is essential.

• Look around for visible water stains on the drywall and subfloor, particularly on concrete.

• Sika-DriTac does not warrant the installation of Sika-DriTac adhesives over non-approved concrete sealers and coatings. Contact Sika-DriTac for a list of approved concrete sealers.

CONCRETE SUBFLOORS

Concrete should be at least 60 days old. Inspect the concrete before installing flooring over it. First inspect for any wetness at the base of the drywall or for visible signs of moisture on the concrete. Second, test for moisture. Use a Calcium Chloride Method Test or Relative Humidity Test for reliable concrete testing. The results should not exceed 3 lbs., per 1,000 square feet over 24 hours, per the ASTM F1869 Calcium Chloride Method Test, or 75% Relative Humidity (RH), per the ASTM F2170 Relative Humidity Method Test. The maximum reading

on concrete for wood installations should not exceed the wood flooring manufacturer’s recommendations. Many wood flooring products

can be installed over lightweight concrete (less then 3000 PSI) or gypcrete, providing the surface is properly prepared. Follow the concrete

manufacturer’s recommendation for the application of a surface hardener/sealer.

PLYWOOD, ORIENTED STRAND BOARD (OSB), OR WOOD SUBFLOORS

CAUTION: Subfloors with high moisture content may shrink at a later date causing cracks to appear in the wood floor. Before installing over any one of these subfloors, test for moisture using a reliable moisture meter such as the Tramex Wood Moisture Meter or equivalent. The moisture content should not exceed 12%. If it is over 12%, either wait until the subfloor is drier or stabilize the subfloor with an additional layer of ¼” plywood. All joints in subflooring materials should have 1/8” expansion space around all panels. If expansion space is not present, cut around and through the panel joints with a circular saw. When installing a plywood sheet subfloor over concrete, use a ¼” x ¼” x ¼” square notched trowel to apply adhesive. Score 3/8” deep every 8 to 10 inches on 4’ x 4’ sheets of ¾” exterior. Set 4’ x 4’ sheets into wet adhesive. Apply weight as necessary and allow to cure overnight.

WOOD INSTALLATIONS

• Wood Flooring should acclimate to “live-in” temperature and humidity conditions (please follow manufacturer’s specifications). Job site environment should be at “live-in” conditions at time of installation. Job site environment should be maintained at “live in”conditions at all times.

• To start installation, create a starting line and secure a straight edge or backer board at this line.

• Trowel DriTac 9100 adhesive onto the subfloor and lay the wood into the adhesive immediately. Trowel only as much adhesive as you can install wood flooring in 30 minutes. The adhesive will dry faster in drier climates.

• Occasionally check for transfer of adhesive to the back of the wood flooring. If adhesive transfer is less than 90% to the back of the wood flooring, scrape up the adhesive and spread fresh DriTac 9100 Contractors Choice.

• Keep the flooring tight as you install. Install wood against the backer board secured at the starting line. The first five or six rows should be interlocked with releasable or painter’s tape, securing the floor from movement during installation. Continue to use tape as necessary. Check with wood manufacturer for list of approved tape manufacturers.

• Allow for expansion in all wood flooring installations. Follow manufacturer’s recommendations.

• Roll the floor with a 100 lb. roller every two to three hours during and immediately after installation.

• When the installation is complete, fill expansion with wedges or cork stripping to hold the floor tightly in place. Remove wedges or cork stripping after floor has set to allow for normal expansion.

• Allow flooring to “breathe”. Do not cover floor with nonporous material such as plastic or vinyl.

• Restrict heavy traffic and furniture placement for 24 hours after installation.

• Allow unfinished wood flooring to acclimate to its new environmental conditions prior to sanding.

• Apply weight to any bowed boards to ensure that the wood flooring adheres securely to the subfloor.

REUSE OF PARTIAL CONTAINERS

Cover adhesive in the pail with a plastic trash bag or two layers of plastic film. Put lid on tightly. Turn over pail. This will seal contents from outside air. To open container, take off lid, cut plastic and remove thin layer of cured adhesive on surface.

VENTILATION

Installers should provide adequate cross-ventilation during and for 24 hours after installation.

KEEP FROM FREEZING

It is necessary to keep this adhesive from freezing. If the adhesive freezes, it cannot be used.

PRECAUTIONS

KEEP OUT OF REACH OF CHILDREN. Avoid contact with skin, eyes and clothing. Wash thoroughly after handling. Avoid breathing vapors. Use only with adequate ventilation. Use impervious gloves, eye protection and if TLV is exceeded or if used in a poorly ventilated area, use NIOSH/MSMA approved respiratory protection in accordance with applicable federal, state and local regulations. DO NOT take internally. Empty container may contain hazardous residues.

FIRST AID

In case of eye contact, flush thoroughly with water for at least 15 minutes. SEEK IMMEDIATE MEDICAL ATTENTION. In case of skin contact, wash affected areas with soap and water. If irritation persists, SEEK MEDICAL ATTENTION. Remove and wash all contaminated clothing. If inhalation causes physical discomfort, remove to fresh air. If discomfort persists, SEEK MEDICAL ATTENTION.

INSTALLER RESPONSIBILITY

These directions are general guidelines for flooring installations. It is the responsibility of the installer to determine proper drying time of the adhesive, trowel size to be used and acceptability of subfloor conditions. Installations must also be in accordance with flooring manufacturers recommendations. Only flooring that is approved for glue down installations by the flooring manufacturer can be used with DriTac 9100. Floors installed with DriTac 9100 are not warranted against damage caused by wet mopping, flooding, plumbing leaks or other extraordinary circumstances. For any installation not herein recommended, contact Sika-DriTac before proceeding.

CLEANING OF TOOLS

To remove adhesive from the surface of the wood, use a damp cloth. If the adhesive has already dried on the surface, use mineral spirits to remove. To remove adhesive from tools, clean with water immediately upon completion of installation.