2011

Boston, Massachusetts

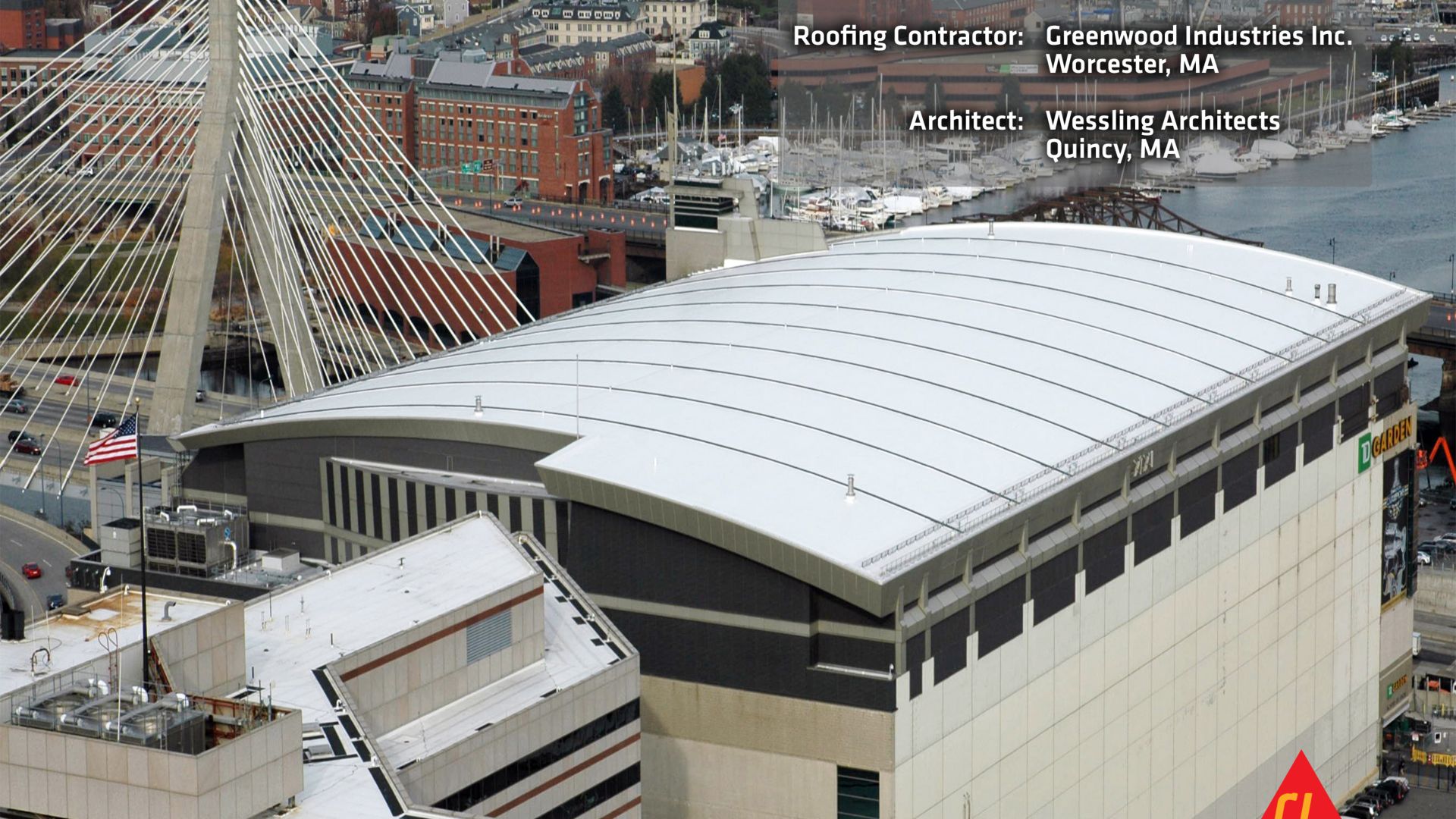

RhinoBond Roof System Meets TD Garden Goals

As home to the six-time NHL Stanley Cup Champion Boston Bruins and the 17-time NBA champion Boston Celtics, the TD Garden has seen many examples of superlative teamwork within its hallowed walls. However, it was teamwork outside the sports arena that was in play when it came time to replace the existing, aged PVC roof.

“There were numerous problems with the old roof, including billowing, which caused weaknesses in the system and created leaks,” said John Karman, senior project manager, building envelope specialist for Wessling Architects of Quincy, Massachusetts.

“We had been chasing annoying drips for 15 years,” explained Jason Beckett, director of operations for Delaware North Companies – Boston, the owners of the building. “TD Garden can’t tolerate roof leaks — we can’t have anything interfere with a game or event, or spoil the experience for the fans.”

Wessling Architects recommended using the Sikalastic RoofPro Liquid Coating in the building’s large north and south side gutters and a Sika Sarnafil RhinoBond Roof System on the barrel roof. “We believe the Sarnafil membrane is one of the best PVC roofing membranes in the market,” Karman stated. “It is a proven product, has heat-weldable seams, and the Sika Sarnafil technical representatives provide a very high level of services. Plus, it is aesthetically pleasing, which was important on such an iconic and visible roof.”

The RhinoBond system from OMG Roofing Products of Agawam, Massachusetts was chosen as the membrane attachment system. RhinoBond is based on electromagnetic induction welding and uses the same fastener and plate to secure both the insulation and the membrane to the roof deck without penetrating the roofing cover. This creates a roofing system with improved wind performance that requires 25 to 50 percent fewer fasteners and plates than a roof mechanically attached at the membrane seams.

And since the fastening points are spread out across the roof deck in a grid-pattern rather than concentrated in the seams of the membrane, the wind uplift load is distributed more evenly. The result is less point loading on each fastener and less billowing, enabling the system to achieve higher wind ratings with fewer fasteners.

“RhinoBond offered sustainability, uniform distribution of fasteners, and economy,” Karman remarked. “It made all the sense in the world.”

Owner

Delaware North Companies, Inc. - Boston

Roofing Contractor

Greenwood Industries, Inc.

Millbury, Massachusetts

Architect

Wessling Architects

Quincy, Massachusetts

Roofing System

RhinoBond Roof System using 72 mil

Sarnafil® S 327 membrane in white

(barrel roof) and SikalasticRoofPro

Liquid Coating (in gutters)

Project Size

156,000 square feet

Selecting a Team

Greenwood Industries of Millbury, Massachusetts was contracted to replace the various roof and gutter systems in a two-year, phased project. The first phase involved installing the Sikalastic RoofPro Liquid Coating on the 10,317 square feet of gutter in conjunction with parapet wall reconstruction and masonry thru-wall flashing coordination. “We used a liquid coating on these portions because of durability and flashing issues with the safety railing,” Karman explained. “Fortunately, since this was a Sika Corporation product it integrated smoothly with the Sarnafil membrane.”

The second phase involved replacing the barrel roof, but had to be delayed for a somewhat unexpected but welcomed reason — the Boston Bruins extended their schedule in the Spring of 2011 by progressing in the playoffs and winning the Stanley Cup. “It was an unusual predicament for me,” David S. Klein, president of Greenwood Industries said. “I was rooting for the Bruins to go all the way, but that meant my start date kept getting pushed back.”

Power Play

When work finally did begin in late June, Greenwood removed 156,000 square feet of the existing roof, which was recycled by Sika Sarnafil into new roofing membrane products. Approximately 113,000 square feet of insulation was also recycled.

A gypsum substrate board was first installed followed by the continuous self adhered vapor barrier. Over this 4.0 inches of insulation with an R value of 27 was installed. The Sarnafil membrane was then installed using the RhinoBond induction welding.

“I love RhinoBond’s speed and ease of installation,” Klein stated. “As soon as you roll out the membrane you can start doing seams right away, which makes the roof watertight much sooner. Our 20-person crew was installing 15,000 to 25,000 square feet of roof a day, which is ten to 15 percent faster than with a mechanically attached system. I try to get most jobs switched to a RhinoBond system.”

Preventing a Wash Out

Thanks in part to the installation speed of the RhinoBond system, Greenwood Industries was on track to finish the roof installation three weeks early, despite the late start date. But then Hurricane Irene threatened.

“We spent three days demobilizing equipment, and removing materials from the roof and securing them on the ground in preparation for Irene,” Klein said. “We lost almost a week of work because of that storm.”

In the end, the roof was completed on time and to everyone’s satisfaction, thanks in large part to teamwork. “There was tight communication with the entire design team and we were all in tune to what was going on,” stated Karman. “We shared mock-ups, had OMG and Sika Sarnafil people on site, did pull tests together — it was definitely a team effort.” Beckett added, “Sika Sarnafil representatives were very experienced, knowledgeable and committed to making sure the application was done correctly, and Greenwood Industries was fantastic. We were very pleased with everyone’s work.”

It was this professionalism that earned Greenwood Industries First Place in Sika Sarnafil’s 2011 Contractor Project of the Year, Low Slope Category.

A Triumphant Team

The new roof survived Irene and continues to do well. “The billowing problem is gone and there are no leaks,” Beckett remarked. “This was a great collaborative effort, and everyone was dedicated to make this high profile roof something they could be proud of.”

Thanks to the teamwork of Greenwood Industries, Wessling Architects, Delaware North Companies, Sika Sarnafil, and OMG Roofing Products, the roof on the TD Garden is performing at top form — just like the sports teams underneath it.